Related Articles

Print barcode horizontally or vertically

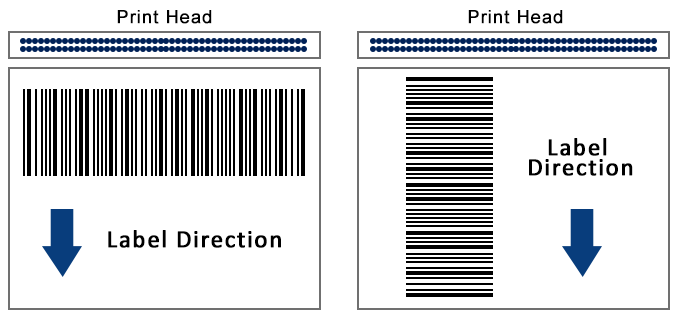

There are two ways to print barcodes: horizontally (picket fence) and vertically (ladder). There are advantages and disadvantages to each method. In picket fence, the bars are printed parallels, while in ladder form bars are printed in perpendicular to the direction of printer’s printing head travels.

Picket fence and ladder orientation of barcode

Both phrases specify which way the barcode will print across the ribbon.

Barcode positioning and presentation on a product—vertically or horizontally—are related to orientation.

The names "picket fence" and "ladder" are used to describe barcode orientation.

When a label is in "picket fence" orientation, the lines are parallel to how the label is moving through the printer. As a consequence, a picture of a picket fence is reflected in the barcode. Because of the way they are printed, these barcodes have a higher quality picture and straighter edges. They are simple to read and scan as a result.

In a "ladder" arrangement, the lines are parallel to the label's motion as it passes through the printer. This ladder-like up-and-down design is most effective on cylinder-shaped items like bottles and cans.

Picket fence orientation cannot correctly follow the curvature of these uniquely shaped objects, making it impossible for the scanner to obtain a reliable reading. The barcode's vertical orientation is a simple solution for shaped objects.

For ease of scanning, barcodes should be put in a clear and accurate area and stay away from irregular planes and corners while choosing the location.

Printing method to choose - horizontal or vertical:

Picket Fence (Horizontal):

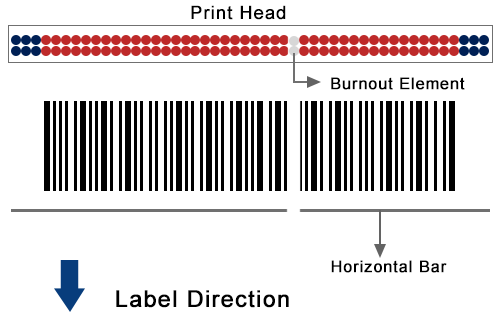

The best feature of printing barcodes horizontally (picket fence) is that the edges are incredibly sharp and clean because the individual print head parts are consistently heated for a predetermined amount of time. Cleaner barcodes are easier for any kind of scanner to read and are less likely to cause mistakes in your inventory and workflow.

The drawback of printing barcodes in picket fence orientation is that if a heated element were to accidentally burn out, a blank line would be left in the middle of the barcode, making it impossible to read and resulting in waste. You can add a horizontal line to the top or bottom of the barcode to fix this problem, but only if you stay inside the barcode's quiet zone. If a burn out issue arises, it will be readily apparent as a break in the horizontal bar. This will alert the user to change the print head and the problematic barcodes as soon as possible.

Ladder (Vertical):

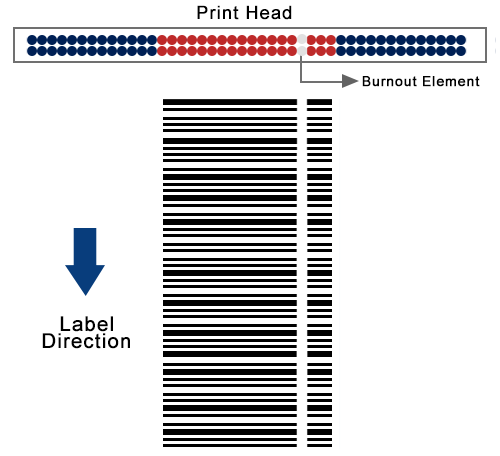

If you choose a ladder orientation, you can see that a defective print head is simple to see since it leaves a white gap all the way across the barcode. It should be noted that this barcode can still be scanned, allowing for the continuation of label printing. The ladder arrangement gives the line operators enough time to gradually replace the print head.

There are some disadvantages of ladders that they are unfortunately not printed as well as picket fences. For example, the borders may blur, making it harder to read barcodes, especially those with small type. Ladder printing might eventually result in excessive print head wear. As a result, printing ladders at high print rates is not advised. This is due to the fact that the heaters of the printer, which are continually switched on and off numerous times every barcode, might burn out fast at these rates.

Final Verdict:

As we have already discussed, there are benefits and drawbacks to printing barcodes in both horizontal and vertical forms. For the majority of applications, we advise users to print barcodes in horizontal form (picket fence). Without experiencing any burnout, the user may print several barcodes quickly. While the vertical type of barcode printing (the ladder) can have burnout and slow pace which is unacceptable in some industries. It is preferable to use vertical barcodes to identify long, cylindrical items like conical tubes.

You may also like: What types of barcodes can be printed with a barcode printer?