How Shipping Barcodes Bring Your Logistics to the Next Level

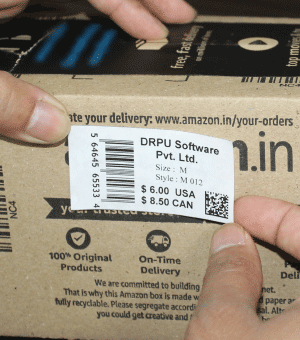

A shipping label may appear straightforward, but it is actually quite complex. A shipping label is included with every delivery package. The shipping labels are specifically designed to be both human and machine-friendly in terms of readability. Orders may be misplaced or mistreated if shipping labels are not clear and precise, making the fulfillment process prone to errors.

Without barcodes, shipping and logistics systems would be inefficient and error-prone. Third-party logistics companies (also known as 3PLs) employ barcodes to successfully manage their warehouses so that they may better serve the corporations for which they provide fulfillment services.

A barcode is a pattern of parallel lines of variable lengths intended to be read by machines and printed on items for stock control. A barcode is usually printed on the shipment's shipping label. It is scanned at every step of the delivery process, from picking up the product to delivering it to the consumer.

A barcode on a shipping package can be used to identify the order and gain access to information such as the goods of the shipment, the customer's identity, the delivery address, and the shipping method. Purchase orders and return paperwork have barcodes that can be used to obtain the right information from the server.

3PL is a solution that lets you outsource operational logistics from warehousing to delivery, allowing you to focus on other aspects of your company.

Third-party logistics companies offer a wide range of supply chain logistics services. This category includes transportation, warehousing, picking and packing, inventory forecasting, order fulfillment, packaging, and logistics services.

Two kinds of barcode are used in 3pl. To get more information, click the card.

-

Recieving Inventories

Experts must ensure that they obtain the correct inventory items when they receive inventory items at fulfillment facilities. They must also confirm that the inventory received came from shipping or parcel shipments. They must scan the barcode embedded in the package or inventory to ensure that the details stated above are accurate.

-

Distributing orders

A shipping barcode will be imprinted on the label put on the package after the order is entirely ready to be dispatched after it has been packaged properly. Courier business will receive the cargo package from the company. Before leaving the fulfillment facility, the carrier will scan the barcode imprinted on the label attached to the package.

-

Receiving return order

There are various types of returns. Customers who return an item to a third-party logistics provider must have it scanned by the third-party logistics provider. Before accepting the order, they thoroughly scan the shipping barcode imprinted on the shipping label. This must be done to ensure that they have received the correct item.

Barcode asset monitoring is a simple and cost-effective method ...

Read MoreQuick Response is abbreviated as QR. It is also known as ...

Read MoreAs tracking and traceability of things in the market place becomes a need ...

Read MoreBarcodes have transformed the world, and they can now be found on ...

Read MoreFuture Of Shipping Industry Barcode Technology

The future of barcode technology in the shipping industry is likely to see continued growth and evolution, with innovations that improve package delivery and logistics in several ways:

How will it continue to improve package delivery and logistics?- Increased automation:

Barcode technology can be used to automate many aspects of the shipping process, from sorting and routing packages to tracking and reporting on delivery times and locations.

- Enhanced tracking and visibility:

As barcode technology continues to advance, we can expect to see even greater tracking and visibility of packages throughout the shipping process. This will help to improve delivery times and reduce errors.

- Integration with other technologies:

Barcode technology can be used in conjunction with other technologies such as RFID and GPS tracking to provide even greater visibility and control over the shipping process.

- Improved accuracy and reliability:

With the development of more advanced barcode scanners and readers, we can expect to see even greater accuracy and reliability in package tracking and delivery.

- Integration with analytics and data management:

Barcode technology can be used to gather valuable data about package delivery times, locations, and other important metrics. This data can then be analyzed and used to improve logistics and optimize the shipping process.

Overall, the future of barcode technology in the shipping industry looks promising, with continued advancements that will improve automation, tracking, visibility, accuracy, and efficiency. These innovations will help to improve package delivery and logistics, making it easier and faster for packages to be delivered to their intended destinations.

The journey of a barcode in the logistics sector-

Barcodes are used at almost every point of the supply chain. They're present when a product is shipped from the producer and when it reaches the end user.

- 1. When the product is sent out by the manufacturer-

When inventory product is sent out by the manufacturer batches are ready to be shipped from the manufacturer to their final destination, a shipping barcode will be added to the label.

- 2. Product delivery to the warehouse-

The Warehouse staff receive inventory product delivery and scan it in when it arrives to ensure that the items and quantities provided by the merchant arrived in the same condition.

- 3. Product recovery from its storage location-

The order picker will know exactly where to get the item(s) and quantities required. When the picker arrives at the warehouse, they will scan the product and location identification.

- 4. Picking shipments in a warehouse-

A label is applied to a box or mailer after it has been packaged. Shipping carriers will pick up packages at warehouses and should scan the package before leaving. This could indicate that the shipment has left the 3PL's possession and in transit.

- 5. While the product is being transported-

When the box is delivered, the carrier should scan it to get a more precise picture of its whereabouts, which will come in handy if it is delayed for whatever reason. Before beginning its journey to the customer, it should be scanned at a nearby facility.

- 6. The item arrived at its target destination-

When a package arrives at its final destination, the carrier will scan it once again to check that it is in good condition. At this point, the customer should have received the order. The package may be returned to a nearby processing center until a fresh delivery attempt is made.