Different Types and Features Of Barcode Label Software

Available Different Types of Barcode Maker Software

There are different types of barcode makers available on the market, each with its own unique features and capabilities. Here are some of the most common types of barcode makers:

-

Barcode Scanner and Printer Bundles:

These are packages that include both a barcode scanner and printer, along with software for creating and printing barcodes. They are ideal for businesses that need a complete barcode solution.

-

Desktop Barcode Software:

These are software programs that are installed a computer and allow users to create and print barcodes. They offer features, customization options than online but require a one-time purchase.

-

Barcode Label Makers:

These are hardware devices that allow users to design and print barcodes directly onto labels or tags. They are ideal for small businesses that need to create labels in-house.

-

Online Barcode Generators:

These are web-based tools that allow users to create barcodes by entering information into an online form. They are usually free and require no software installation.

Each type of barcode maker has its own advantages and disadvantages, and the selection of the appropriate maker will depend on the specific needs of the user and the application. Factors to consider include the type of barcode being created, the volume of barcodes being generated, the level of customization needed, and the budget available.

Types of Barcode Label Application

Barcode software can generate various types of barcodes based on the specific needs of the user. Some of the most common types of barcodes that can be generated using barcode software include:

-

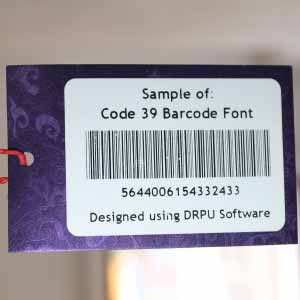

Code 39:

Code 39 is a linear barcode that can encode alphanumeric characters. It is commonly used in inventory management and asset tracking.

-

Code 128:

Code 128 is a high-density linear barcode that can encode a large amount of data, including letters, numbers, and symbols. It is often used in supply chain management and logistics.

-

QR Code:

QR codes are 2D barcodes that can be scanned using a smartphone or other mobile device. They can encode a variety of data, including URLs, text, and contact information.

-

Data Matrix:

Data Matrix is a 2D barcode that can encode a large amount of data, including letters, numbers, and symbols. It is commonly used in manufacturing and logistics.

-

UPC:

UPC (Universal Product Code) is a linear barcode commonly used in retail to identify products and track inventory.

-

EAN:

EAN (European Article Number) is similar to UPC and is also commonly used in retail.

-

ISBN:

ISBN (International Standard Book Number) is a unique identifier assigned to books and other publications. ISBN barcodes are used to identify books and other publications in the publishing industry.

By considering these features when selecting barcode software,can ensure that they have a reliable and effective tool for creating and printing barcode labels.

Feature of Barcode Label Software

When selecting barcode software, there are several features for ensure that the software meets their needs. Here are some of the key features to consider:

- ❖ Barcode symbology support: The software should support the specific barcode symbologies needed for the application, such as Code 128 or QR codes. It should also be able to generate high-quality barcodes that are scannable and readable.

- ❖ Label design capabilities: The software should have a user-friendly interface that allows for easy label design and customization. It should allow users to customize the size, layout, font, and color of the labels.

- ❖ Data integration: The software should be able to integrate with databases and other systems to import data and create labels automatically. This can save time and reduce the risk of errors.

- ❖ Batch printing:The software should allow users to print multiple labels at once, which can save time and improve efficiency.

- ❖ Error correction: The software should have built-in error correction capabilities that can detect and correct errors in the barcode data. This can help to prevent errors and ensure that the labels are accurate.

- ❖ Security: The software should have security features to protect sensitive data, such as encryption and user authentication.

- ❖ Compatibility: The software should be compatible with the operating system and hardware being used, such as printers and barcode scanners.

Benefits of Using Barcode Label Software

The benefits of using barcode label software include:

-

➤ Increased Efficiency:

Barcode label software can help automate and streamline manual data entry tasks, which can save time and reduce errors.

-

➤ Improved Accuracy:

Barcodes are more accurate than manual data entry, which reduces the risk of errors that can lead to costly mistakes.

-

➤ Enhanced Traceability:

Barcodes enable businesses to track items and transactions more easily, which can help identify issues and improve inventory management.

-

➤ Cost Savings:

By reducing errors and increasing efficiency, barcode label software can help businesses save money on labor costs, reduce waste, and optimize inventory levels.

-

➤ Customization:

Barcode label software can be customized to meet the specific needs of a business, including label design, data capture options, and integration with other systems.

-

➤ Scalability:

Barcode label software can be easily scaled up or down to accommodate changes in business needs, such as growth, new product lines, or changes in technology.

-

➤ Better Customer Service:

Barcode label software can help businesses provide faster and more accurate service to customers, which can lead to increased customer satisfaction and loyalty.

Overall, barcode label software can help businesses improve their operations, reduce costs, and provide better customer service, which can lead to increased profits and a competitive advantage.

Hardware and Software Requirements Of Barcode Label Maker

The hardware and software requirements for using a barcode label maker will depend on the specific model and manufacturer. However, here are some general hardware and software requirements that are commonly needed:

Hardware Requirements:| Computer: |

A computer is necessary to run the software that controls the barcode label maker. The computer should meet the manufacturer's specifications for operating system, processor speed, and memory. |

| Printer Barcode Label: |

A printer is required to print the barcode labels. The printer should be compatible with the label maker software and be capable of printing high-quality, durable labels. |

| Barcode Scanner: |

A barcode scanner may be required to test the labels and ensure that they can be scanned accurately. |

| Label Design Software: |

Barcode label makers typically come with software that allows users to design and print labels. The software should be compatible with the operating system of the computer. |

| Barcode Symbology Support: |

The software should support the specific barcode symbologies needed for the application, such as Code 128 or QR codes. |

| Database Support: |

The software may need to connect to a database to access the information that will be encoded in the barcode labels. |

Overall, the specific hardware and software requirements for a barcode label maker will depend on the manufacturer and the application. the manufacturer's specifications and recommendations before purchasing a barcode label maker to ensure that it meets their needs and requirements.

-

Paper Labels:

Paper labels are the most common type of barcode labels and are typically used for general-purpose applications, such as inventory management and product identification. They are available in a variety of sizes and shapes.

-

Polyester Labels:

Polyester labels are more durable than paper labels and are ideal for use in harsh environments or where labels may be exposed to chemicals or moisture. They are often used for asset tracking and outdoor applications.

-

Vinyl Labels:

Vinyl labels are similar to polyester labels but are more flexible, making them ideal for use on curved surfaces or where the label may be subject to stretching or bending.

-

Tamper-Evident Labels:

Tamper-evident labels have a special adhesive that makes it clear if someone has attempted to remove or tamper with the label. They are often used for asset tracking, security applications, and medical labeling.

-

Ultra-Destructible Labels:

Ultra-destructible labels have a special adhesive that makes them virtually impossible to remove without destroying the label. They are often used for asset tracking and security applications.

-

Removable Labels:

Removable labels have a low-tack adhesive that allows them to be easily removed without leaving residue. They are often used for temporary labeling applications.

Factors to consider include the environment in which the label will be used, the type of surface the label will be applied to, and the level of durability required.