Characters That Can be Encoded in a UCC/EAN-128 Barcode

The data encoded in a UCC/EAN-128 barcode is divided into three parts: the Application Identifier (AI), the data field, and a checksum digit. The AI is a two to four-digit code that identifies the meaning of the data that follows. The data field is the actual data that is being encoded. The checksum digit is used to ensure the accuracy of the barcode data.

The UCC/EAN-128 barcode can encode the following types of data:

-

Numeric Data: The UCC/EAN-128 barcode can encode numeric-only data. The data can be from 1 to 18 digits in length.

-

Alphanumeric Data: The UCC/EAN-128 barcode can encode alphanumeric data. This can include letters, numbers, and some special characters. The data can be from 2 to 30 characters in length.

-

Binary Data: The UCC/EAN-128 barcode can encode binary data. This can include non-printable characters such as control codes and extended ASCII characters. The data can be from 1 to 8 bytes in length.

-

Date and Time: The UCC/EAN-128 barcode can encode date and time data. This can include the year, month, day, hour, minute, and second. The data is encoded using the YYYYMMDDHHMMSS format.

-

Currency Data: The UCC/EAN-128 barcode can encode currency data. This can include the currency symbol and the amount. The data is encoded using the ISO 4217 currency code followed by the amount.

-

Measurement Data: The UCC/EAN-128 barcode can encode measurement data. This can include length, weight, and volume. The data is encoded using the unit of measurement and the value.

-

Serial Number Data: The UCC/EAN-128 barcode can encode serial number data. This can include the manufacturer's serial number or the product's serial number. The data is encoded using the AI (21) followed by the serial number.

-

Variable Measure Data: The UCC/EAN-128 barcode can encode variable measure data. This can include the weight or volume of a product. The data is encoded using the AI (310n) followed by the value.

-

Lot Number Data: The UCC/EAN-128 barcode can encode lot number data. This can include the lot number of a product. The data is encoded using the AI (10) followed by the lot number.

-

Location Data: The UCC/EAN-128 barcode can encode location data. This can include the location of a product within a warehouse or storage facility. The data is encoded using the AI (254) followed by the location code.

Overall, the UCC/EAN-128 barcode can encode a wide range of data types, making it a versatile choice for many applications.

UCC/EAN-128 Barcode Read and Decoded Method

-

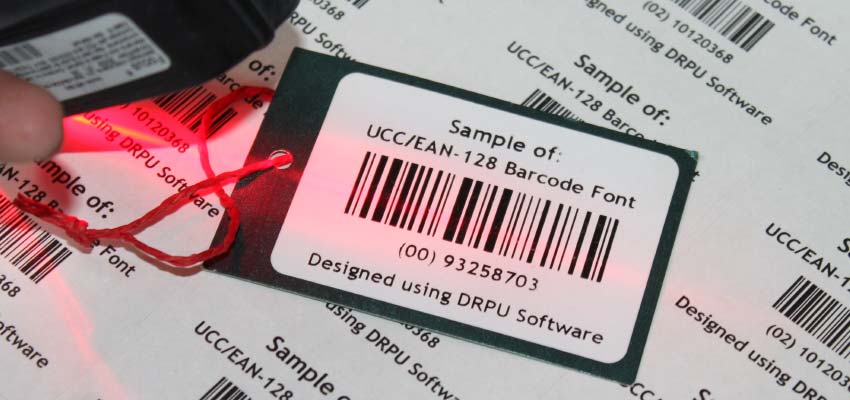

The scanning process involves shining a beam of light onto the barcode and measuring the amount of light that is reflected back. The scanner then converts the reflected light into an electrical signal, which is processed to determine the pattern of bars and spaces in the barcode. This information is then decoded into a numerical or alphanumeric code that can be used to look up product information or track inventory.

-

One common method of decoding UCC/EAN-128 barcodes is through the use of software that can read and translate the barcode information. This software can be installed on a computer or mobile device and used to scan barcodes using the device's camera or a barcode scanner.

-

Another method of decoding UCC/EAN-128 barcodes is through the use of hardware devices such as barcode scanners. These scanners use a light source and a sensor to detect the barcode pattern and convert it into an electrical signal. The signal is then sent to a computer or other device, which can then decode the information and use it for various applications.

-

UCC/EAN-128 barcodes can also be decoded using handheld barcode scanners, which are portable devices that can be used to scan barcodes in a variety of settings. These scanners typically have a trigger or button that the user presses to initiate the scanning process, and they can be connected to a computer or mobile device to transfer the barcode information.

Overall, the decoding process for UCC/EAN-128 barcodes is relatively simple and can be performed using a variety of devices and technologies. The key is to ensure that the barcode is scanned or imaged correctly to ensure accurate decoding of the information encoded within.

Advantages of Using UCC/EAN-128 Barcode

UCC/EAN-128 barcode, also known as GS1-128, is a highly versatile barcode used in various industries for supply chain management, inventory tracking, and data management. Here are some of the advantages of using UCC/EAN-128 barcode:

-

Improved Supply Chain Management:

UCC/EAN-128 barcode enables real-time tracking and monitoring of inventory, providing a more efficient and effective supply chain management system. It facilitates accurate and timely information exchange between trading partners, reducing manual errors and delays in delivery.

-

Greater Data Capacity:

UCC/EAN-128 barcode can store more data than traditional barcodes. It can hold alphanumeric characters, including GS1 Application Identifiers (AIs), which allow the encoding of various data elements such as product ID, batch number, and expiry date. This makes it easier to track products throughout the supply chain and helps prevent counterfeiting and theft.

-

Enhanced Data Accuracy:

The use of AIs in UCC/EAN-128 barcode helps ensure data accuracy, as each data element has a specific meaning and format. This reduces the chances of errors in data entry and processing, leading to better inventory management and customer satisfaction.

-

Easy Integration:

UCC/EAN-128 barcode can be easily integrated with existing inventory management systems, making it easy to implement without significant investment in new technology or software. It can also be printed on different types of surfaces, including labels, tags, and packaging materials.

-

Compliance with Industry Standards:

UCC/EAN-128 barcode is compliant with global industry standards set by the GS1 organization. This ensures that products can be identified and tracked across borders, making it easier for businesses to expand globally.

-

Improved Efficiency and Productivity:

With UCC/EAN-128 barcode, businesses can streamline their operations, reducing manual errors, and increasing productivity. This leads to cost savings, better inventory management, and improved customer service.

Overall, UCC/EAN-128 barcode offers several benefits that can help businesses improve their operations, increase efficiency, and enhance customer satisfaction.

Limitations of Using UCC/EAN-128 Barcode

UCC/EAN-128 barcodes have several limitations that should be considered when deciding whether to use them for a particular application. Here are some of the main limitations:

-

Requires a Larger Amount of Space: UCC/EAN-128 barcodes require more space than some other types of barcodes, such as Code 39 or UPC barcodes. This can be a limitation if space is limited on the item being marked or if the barcode needs to be printed in a smaller size.

-

Complexity of Encoding: The UCC/EAN-128 barcode is a complex barcode, which requires specialized software and knowledge to create and manage. This can be a limitation for businesses that lack the resources to implement the barcode effectively.

-

Limited Character Set: While the UCC/EAN-128 barcode can encode a wide range of characters, there are some limitations to the character set that can be used. This can be a limitation if the application requires the use of characters that are not supported by the barcode.

-

Scanning Accuracy: The UCC/EAN-128 barcode requires a high degree of scanning accuracy to be read successfully. This means that the barcode must be printed clearly and must not be damaged or distorted in any way.

-

Limited Scanning Distance: The UCC/EAN-128 barcode has a limited scanning distance compared to some other types of barcodes. This means that the barcode must be close to the scanner in order to be read successfully.

-

Requires Specialized Hardware: The UCC/EAN-128 barcode requires specialized hardware to be read successfully. This can be a limitation for businesses that do not have the necessary equipment to support the barcode.

-

Cost: The UCC/EAN-128 barcode can be more expensive to implement than some other types of barcodes, due to the specialized software and hardware that are required. This can be a limitation for businesses that are operating on a tight budget.

Conclusion: The UCC/EAN-128 barcode is a powerful and flexible barcode that can be used for a wide range of applications. However, it is important to consider the limitations of the barcode before implementing it to ensure that it is the right choice for the specific use case.

Devices That Can Read UCC/EAN-128 Barcode

UCC/EAN-128 barcodes are widely used in the supply chain industry to track and manage products. To read these barcodes, there are several types of devices available, including handheld scanners, fixed-mount scanners, and mobile devices with built-in cameras. In this guide, we will explain each of these devices and their capabilities.

-

Mobile Devices with Built-in Cameras:

Mobile devices, such as smartphones and tablets, with built-in cameras can also be used to read UCC/EAN-128 barcodes. They are a convenient and cost-effective solution for businesses that need to scan barcodes on the go. Mobile devices use image-based technology to capture an image of the barcode, and specialized software is used to decode the data. Mobile devices are ideal for businesses with mobile workforces, such as delivery drivers, field service technicians, and sales representatives. They allow workers to scan barcodes and access product information and inventory data in real-time, improving efficiency and accuracy.

-

Fixed-Mount Scanners:

Fixed-mount scanners are designed to be mounted in a fixed location, such as on a conveyor belt or a production line. They are used to read UCC/EAN-128 barcodes on products as they move through the production or distribution process. Fixed-mount scanners are typically image-based scanners that use a camera to capture an image of the barcode.

Fixed-mount scanners can be integrated into automated systems, such as warehouse management systems, to streamline the process of scanning and tracking products. They are also used in quality control processes to ensure that the correct products are being produced and packaged.

-

Handheld Scanners:

Handheld scanners are the most commonly used devices for reading UCC/EAN-128 barcodes. They are portable and easy to use, making them ideal for scanning barcodes on products, boxes, and pallets. Handheld scanners use laser or image-based technology to read barcodes. Laser scanners emit a beam of light that reflects off the barcode, while image-based scanners use a camera to capture an image of the barcode.

Handheld scanners can be corded or cordless. Corded scanners are connected to a computer or mobile device via a cable, while cordless scanners use Bluetooth technology to transmit data to a computer or mobile device wirelessly. Cordless scanners are more convenient to use, as they allow users to move around freely while scanning.

Conclusion: There are several types of devices available for reading UCC/EAN-128 barcodes, including handheld scanners, fixed-mount scanners, and mobile devices with built-in cameras. Each device has its own strengths and weaknesses, and the choice of device will depend on the specific needs of the business. Handheld scanners are the most commonly used devices and are ideal for businesses that need to scan barcodes on products, boxes, and pallets. Fixed-mount scanners are used in production and distribution processes to read barcodes on products as they move through the process. Mobile devices with built-in cameras are a cost-effective solution for businesses with mobile workforces.