How to Use Barcodes with Delivery Tracking Software

Delivery tracking software uses a tracking barcode to receive, transfer, and deliver each product with minimum effort. Barcode also used in mailrooms to manage and track packages and deliveries to individuals, buildings, offices, and rooms of their intended recipient. From the moment a package is delivered, you can easily track when it arrived, where it was sent, and who finally received it, all with a chain of responsibility and confirmation.

Every day, companies lose many assets each year because of items that are misplaced, lost, or stolen. Whether you are tracking IT assets, vehicles, tools, documents, etc., having reliable tracking software will help you prevent losing valuable assets and money.

How do Barcodes Work?

Workflow Status Tracking

Your business can track the overflow status of order with barcode system. Barcodes make it possible to track inventory so precisely, reducing the chance of human error when tracking inventory item, which leads to smoother supply chain management. Barcodes play an important role in "supply and demand", including the distribution and transport of products to the customer, and they are used to control the manufacturing process (production line).

Order Location Tracking

Barcodes are used to track the movement of products as they are distributed to customers. You can keep track of the location of shipments in transit using a barcode, and the system will automatically update the product’s current status, availability, and location. In shops and supermarkets, the barcodes on the packaging of items are used by computer systems to monitor sales and order further supplies.

Tracking Product Information and History

A barcode is encoded information into a visual pattern with a barcode scanner and tracks product history. Barcodes are an efficient means of identifying individual products in inventory. Barcodes are practically an error-free way to assign product information to a specific item, such as lot number, product ID, and many others. Using a barcode scanner identify a product and get more information about it, such as how long it has been in stock.

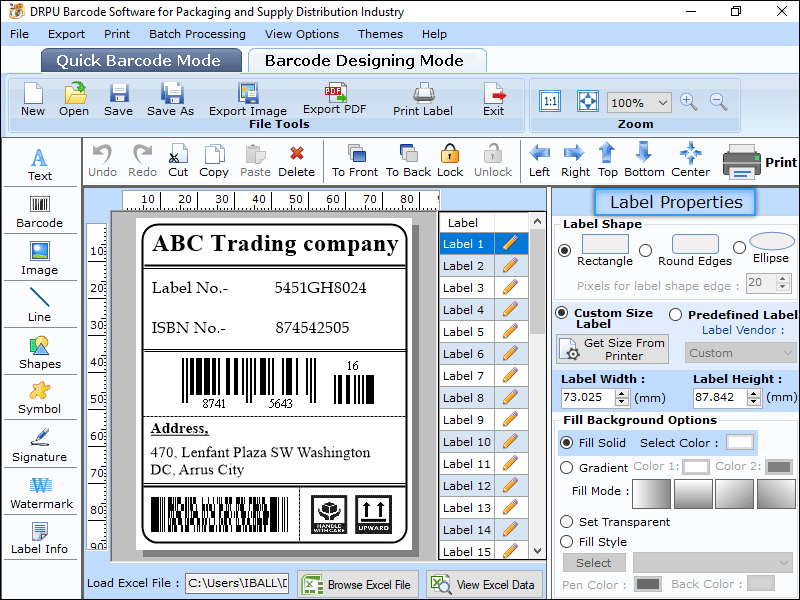

How to Generate Barcodes for Delivery Tracking

- You’ll need to choose software to create your barcodes. Business barcode maker software is the best tool to generate barcodes for tracking. With software, it’s time to determine the types of barcodes you’ll want to use. Some of the most common types of barcodes are QR codes, EAN13, Code 128, etc.

- Barcode type you choose will depend on how much information you want to encode into the barcode. A numeric UPC may be sufficient for smaller inventories where you only need to track product and manufacturer information, whereas a QR code might be better for tracking vast numbers of different items.

- When you have a barcode type you like, use "Barcode Generator Software" to create the barcodes for each product. Last of all, print the barcode and place it on each item. Now you’ll be able to track your order wherever it goes, whether you’re sending it across the nation or simply moving it around in your warehouse. Every time a product moves to a different location, it gets scanned many times, meaning it’s less likely to get lost. If an order is missing, it’s easier to track it down.

Key Benefits of Barcodes for Tracking

Efficiency & Cost-Effectiveness

Using unique barcodes is a useful tool for labeling and tracking samples in your laboratory. It simplifies the process of tracking the correct samples and types of equipment that are needed to perform experiments.

Easy Assembling and Disassembling

Resources such as money, labor, stationery, and time are significantly spent on setting up and disassembling attendance and check-in counters. With barcodes, these get reduced at least. They require less check-in time and fewer staff members.

Simple Preparation

As the Smartphone barcode scanners are simple and easy to use, there is no need for special training for the event staff members. The event organizers only need to test the chosen scanner before the event and don’t require laptops for entering attendance details.

Faster Moving Queue

Implementing a barcode-based digital queue system into your entry process will eliminate the danger of long queues. Barcode technology takes only a few seconds per item to check-in, so the process will be fast and simple.