Barcode Inventory System: Uses, Types, Benefits, and More

What is Barcode Inventory System?

Barcode inventory system is a method that helps businesses track inventory, minimize errors, save on payroll, and improve their ordering faster and easier.

While it’s possible to manage inventory systems by hand or with spreadsheets, these methods are complicated and prone to human error. Both hardware and software systems can automate inventory systems.

An inventory control system can account for anything from clothing to food if it can be quantified and labeled. Inventory management became more crucial during this COVID era, as back-to-back lockdowns posed a major challenge for businesses.

Barcode Inventory has proved to be of great assistance in tracking assets and maintaining a supply chain. In the e-commerce world, many merchants utilize barcode inventory management to streamline their operations.

Why use Barcodes?

As a business becomes more complex, certain tasks need to be automated to keep up with demand. Barcode labeling system can help solve both of these problems. Instead of logging SKUs into a spreadsheet, simply scan the barcode, which then updates your inventory control records in a matter of seconds.

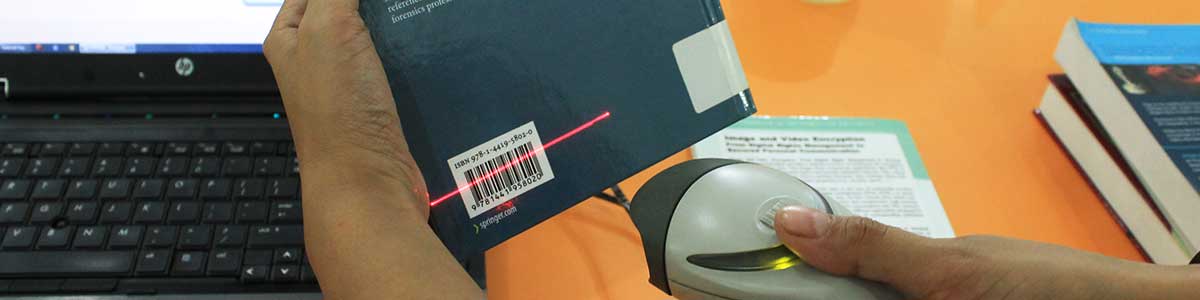

Barcode is not useful by itself, but rather only once the products are labeled with the barcodes and can be scanned. The scanner shines LED or laser light onto the barcode, which is then reflected into a sensor in the scanner. The sensor can discern between black and white spaces in the barcode as each reflects a different amount of light.

Whether the scanner used is handheld, pen-style, or embedded, scanning the barcode will produce an identifying string, which is then matched to a record in the inventory.

Types of Barcodes used in Inventory

The type of barcode you choose depends on how much product information you need to encode into them. If you have a relatively small inventory system and only need to track limited product information, 1D barcodes will likely be sufficient.

On the other hand, if you have an expansive database of SKUs and need to track detailed information about inventory, 2D barcodes (like QR codes) are likely the better option than 1D barcodes.

1D Barcode:

2D Barcode:

How does a Barcode Inventory System Work?

Before implementing a barcoding system, it’s important to determine whether it’s right for your business requirements. You can easily store inventory in a warehouse, and managing hundreds or even thousands of products in a warehouse can be daunting without the ability to track them.

Even if you think you can manage without a barcode system, the vendors you work with will require barcodes for the items they purchase from you.

A barcoding system enables you to do real-time inventory analysis of items in your warehouse. Instead of scrambling to find the latest inventory report, you can simply log into your computer and see every product you have in stock and where it’s located.

Barcode encodes information into a visual pattern of black and white spaces. When read by a barcode scanner, the information about the product is collected and sent to a centralized computer system that automatically tracks the item and the relevant information associated with it.

Choose a Barcoding Inventory Software

It’s important to take into consideration the needs of your business, the capabilities, benefits, and challenges of available barcode inventory systems, then create barcode labels.

You will use “Business Barcode Maker software” to create the barcodes that correspond with your inventory. The software creates a unique code for each item.

Business barcode maker tools are designed to generate labels for tracking inventory levels, sales, orders, deliveries, and other warehouse or distribution center needs.

Beyond this, Software can help manufacturers create things like work orders, purchase orders, bills of materials, and a wide range of other documents needed for barcode labeling.

Benefits of Using Barcodes for Inventory Control

Improved Efficiency

Barcode warehouse inventory system allows for more accurate operation and faster reading of products data and information. Barcode scanners make the easy operation and tracking of information fast and accurate.

Increased Productivity

Barcode technology helps to increase and boost productivity by updating inventory levels or asset movement digitally. Barcode software has significant streamlined benefits to reduce app training time as well.

Cost-Efficient

Accurate data transfer to the system allows for the efficiency of all ongoing processes in the company. When everything goes smoothly & error-free, it saves lot of money that is lost due to mistakes, or error.

Reduced Errors

Clarity in information entry through scanner technology boosts the organization's business with reduced errors. By using barcode scanning, you bypass tonnes of error-prone processes, like transposing data etc.