Generate, Print, and Scan Interleaved 2 of 5 Barcode

Generating an Interleaved 2 of 5 (ITF) barcode involves several steps, including selecting an ITF barcode generator, specifying the data to be encoded, and configuring the barcode settings. In this essay, we will explore these steps in detail, providing a comprehensive guide to generating ITF barcodes.

-

Step 1: Select an ITF Barcode Generator

The first step in generating an ITF barcode is to select an ITF barcode generator. There are many free and paid barcode generator tools available online, each with their own set of features and capabilities. Some popular ITF barcode generators include Barcode Generator, Online Barcode Generator, and TEC-IT Barcode Studio.

When selecting an ITF barcode generator, it is important to consider factors such as the level of customization required, the volume of barcodes to be generated, and the compatibility with existing software systems. Some barcode generators may be better suited for small-scale applications, while others may be designed for high-volume production environments.

-

Step 2: Specify the Data to be Encoded

Once an ITF barcode generator has been selected, the next step is to specify the data to be encoded. ITF barcodes are primarily used for encoding numeric data, such as product SKUs, serial numbers, or batch codes. To generate an ITF barcode, you will need to provide the numerical data to be encoded in the barcode.

Depending on the barcode generator tool being used, there may be different options for specifying the data to be encoded. Some tools may allow you to input data manually, while others may allow you to import data from a spreadsheet or other data source.

-

Step 3: Configure the Barcode Settings

After specifying the data to be encoded, the next step is to configure the barcode settings. This includes selecting the ITF barcode type, specifying the barcode dimensions, and configuring any additional settings or options.

Selecting the ITF Barcode Type:

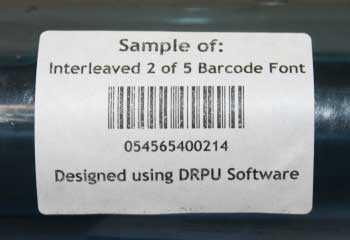

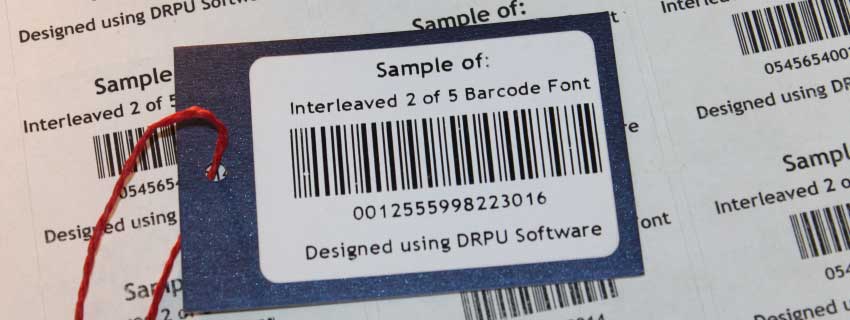

ITF barcodes come in two main formats: ITF-14 and ITF-16. ITF-14 barcodes are 14 digits in length and are typically used for labeling cases or pallets in the retail and logistics industries. ITF-16 barcodes are 16 digits in length and are used for encoding large amounts of numeric data, such as production codes or serial numbers.

Specifying the Barcode Dimensions:

ITF barcodes have specific requirements for their dimensions, including the width of the bars and spaces, as well as the height and width of the barcode itself. The exact dimensions required may vary depending on the application and the type of scanner being used to read the barcode. It is important to consult the documentation for the barcode generator tool being used to ensure that the barcode dimensions are set correctly.

Configuring Additional Settings:

Depending on the barcode generator tool being used, there may be additional settings or options to configure, such as the font type or color of the barcode, the presence or absence of quiet zones around the barcode, and the inclusion of additional text or symbols in the barcode.

-

Step 4: Generate the Barcode

Once the data and settings have been specified, the final step is to generate the ITF barcode. This may involve clicking a "Generate" button within the barcode generator tool, or exporting the barcode as an image or file format such as PNG, JPG, or EPS.

After generating the barcode, it is important to test it using a variety of scanners to ensure that it can be read accurately and reliably. It may also be necessary to print and apply the barcode to the relevant products or packaging materials, following industry best practices for barcode labeling and placement.