-

The UPCA barcode was first developed in the 1970s by a consortium of grocery store chains in the United States, and it quickly became the standard for retail product identification. Today, UPCA barcodes are used worldwide and can be found on a wide range of consumer products, including food and beverages, household goods, and electronics.

-

The UPCA barcode consists of two main parts: the left-hand side and the right-hand side. The left-hand side of the barcode contains the manufacturer's unique identification number, which is assigned by the Uniform Code Council (UCC). The right-hand side of the barcode contains the product's unique identification number, which is assigned by the manufacturer.

-

The UPCA barcode uses a system of bars and spaces to represent each digit of the barcode. Each digit is represented by a unique pattern of bars and spaces, with the width and spacing of the bars and spaces determining the value of the digit. The UPCA barcode also includes a check digit, which is calculated based on the other 11 digits in the barcode and is used to ensure that the barcode is scanned correctly.

-

One of the benefits of using UPCA barcodes is that they are easy to read and can be quickly and accurately scanned using a barcode scanner. This makes them an ideal solution for retailers looking to streamline their inventory management and tracking processes.

-

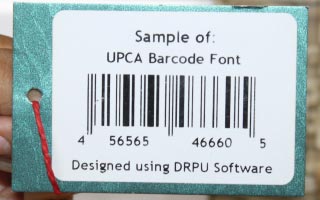

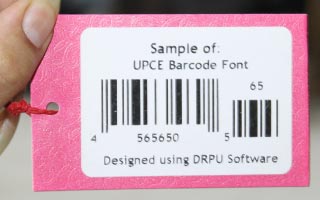

To generate UPCA barcodes, businesses can use specialized barcode software or hardware. Barcode software can be used to generate barcodes in a variety of formats, including vector and raster images. Barcode hardware, such as barcode printers, can be used to print UPCA barcodes directly onto product packaging or labels.

-

In addition to UPCA barcodes, there are several other types of barcodes that are used in the retail industry, including EAN barcodes, which are similar to UPCA barcodes but are commonly used outside of the United States, and GS1 Data Bar barcodes, which are used for smaller items such as fresh produce and baked goods.

In conclusion, Businesses can generate UPCA barcodes using specialized barcode software or hardware, and they are a valuable tool for streamlining inventory management and tracking processes in the retail industry.