It is advised if your inventory comprises high-value products that must be meticulously managed and preserved. Inventory barcoding is an effective approach to handling merchandise. In the current scenario, it takes a couple of minutes to manually write the information related to the product; you may scan a single barcode holding many characters at once. Barcodes are an excellent starting point for effective inventory management and a terrific method to save a lot of time and money. As a result, barcoding your goods will make inventory management considerably faster and easier.

A brief about Barcode Inventory Management:

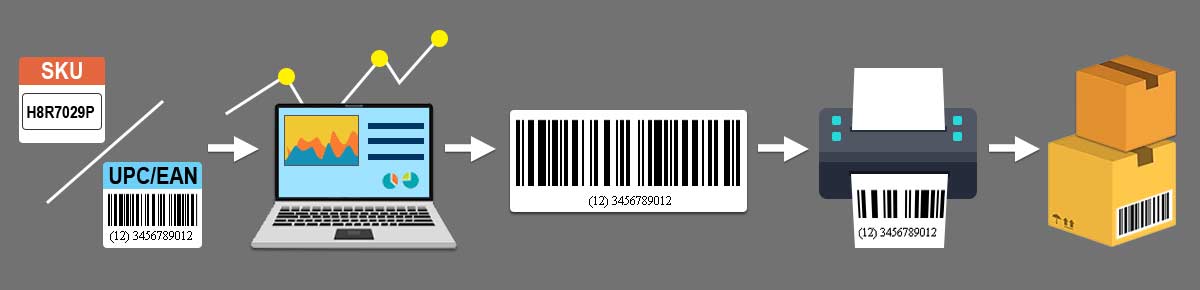

When a product is sold, the barcode is scanned, and the information is transferred to a central database, which records the data and makes beneficial business decisions. Individual barcodes are assigned to items in a barcode inventory system.

When a warehouse worker scans the barcode after choosing a product, the scanner indicates if the item is correct or incorrect. It also keeps track of the operations in your inventory management system, allowing you to retain precise stock levels. Assisting you to keep real-time inventory track and enhance picking speed and accuracy.

How to Create Barcode for Inventory Management:

How to Use Barcode for Inventory Management:

Importance of barcodes for inventory management:

Some of the most notable barcode advantages are listed below:-

In a matter of seconds, you can access your data:

Nobody likes to deal with the tedious paperwork required to obtain inventory information. A worker's time is valuable, and checking every item in inventory might take a long time, slowing down your company's growth. When you use barcodes, all you need is a simple scan to get all the information you need about an item you've added to your inventory program.

Long and time taking processes can be automated:

Organizations may employ barcode systems to speed up activities like inventory counts and audits that were previously time-consuming. Instead of counting each item by hand, your staff can now utilize barcodes to swiftly update inventory counts and investigate any inconsistencies. Barcodes help industries to update and control inventory in real time with ease.

Choosing the Ideal Product:

When people are overworked, they get fatigued and distracted. This is equally true of your selection committee. Customers will receive the incorrect item if you rely on your pickers to choose the correct item every time. When a barcode inventory system is used, the scanner verifies that the correct item is selected. No matter how exhausted or busy they are, selecting the proper thing becomes easy. As a result, the situation of picking the wrong item does not occur. Inventory counts can also benefit from barcode stickers.

Human mistakes are reduced:

By reducing manual input, barcodes improve efficiency and production. Even the most diligent personnel are prone to making serious inventory errors. After all, your work team is comprised of individuals or human beings. You can avoid a lot of mistakes by scanning barcodes instead of transposing data, keeping track of products by hand, mixing up merchandise that looks or sounds identical, confusion in serial numbers, or disorder small columns on an old table. Professionals that use barcode technology works faster.