Introduction Of Industrial 2 of 5 Barcode

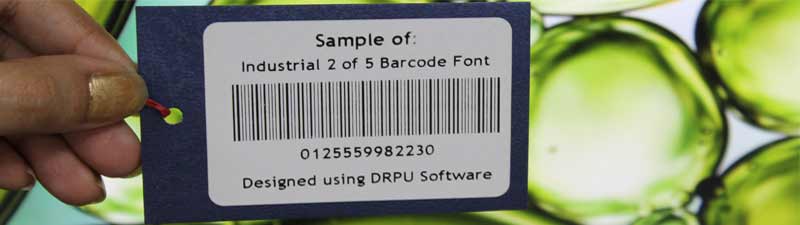

Industrial 2 of 5 (also known as Code 2 of 5 Industrial, Code 2 of 5 Interleaved, or Code 2/5) is a type of linear barcode that is commonly used in warehouse, inventory, and logistics applications. In this article, we will discuss the structure, encoding, advantages, and limitations of Industrial 2 of 5 barcodes, as well as their applications and how to generate and scan them.

Structure of Industrial 2 of 5 Barcode

↠ The Industrial 2 of 5 barcode is a variable-length, two-width barcode that consists of a series of bars and spaces of varying widths. The barcode is made up of a start code, a data code, and an end code. The start code and end code are usually represented by two narrow bars and a wide bar, while the data code is represented by a series of narrow and wide bars.

↠ The Industrial 2 of 5 barcode is an interleaved barcode, which means that pairs of characters are encoded together. The barcode is named "2 of 5" because each character is represented by five bars, two of which are wide and three of which are narrow.

Encoding of Industrial 2 of 5 Barcode

↠ To encode data in an Industrial 2 of 5 barcode, the data must be in a numeric format and must have an even number of digits. The barcode uses a modulo 10 check digit to ensure accuracy, which means that an additional digit is added to the end of the data code to check for errors during scanning.

↠ The encoding process for Industrial 2 of 5 barcodes is straightforward. Each pair of digits is represented by a series of bars and spaces, with the first digit being represented by narrow bars and the second digit being represented by a combination of narrow and wide bars. For example, the digits "1" and "2" are represented by the pattern "NNWN" (where "N" represents a narrow bar and "W" represents a wide bar).

Advantages of Industrial 2 of 5 Barcode

There are several advantages to using Industrial 2 of 5 barcodes in warehouse and logistics applications:

| High Density: | Industrial 2 of 5 barcodes are highly space-efficient and can store a large amount of data in a small space. This makes them ideal for labeling small items or products with limited labeling space. |

| Easy to Generate: | Industrial 2 of 5 barcodes can be easily generated using a barcode generator software or hardware. This makes it easy to create large volumes of barcodes quickly and cost-effectively. |

| Low Cost: | Industrial 2 of 5 barcodes are low-cost to produce and can be printed on a variety of materials, including paper, synthetic materials, or adhesive labels. This makes them ideal for high-volume printing and labeling applications. |

| Compatibility: | Industrial 2 of 5 barcodes are widely recognized and can be read by most barcode scanners. This makes them compatible with most warehouse and logistics systems. |

Limitations of Industrial 2 of 5 Barcode

| Limited Data Capacity: | Industrial 2 of 5 barcodes have a limited data capacity compared to other barcode types, such as Code 128 or QR codes. This makes them less suitable for storing large amounts of data, such as product descriptions or marketing messages. |

| Numeric Data Only: | Industrial 2 of 5 barcodes can only encode numeric data, which means that they are not suitable for applications that require the encoding of alphanumeric or special characters. |

| Check Digit Requirement: | Industrial 2 of 5 barcodes require a check digit to ensure scanning accuracy, which adds an additional character to the data code. This can limit the |

Applications of Industrial 2 of 5 Barcode

Industrial 2 of 5 barcodes have a wide range of applications in various industries due to their simplicity and high data density. Some of the common applications of Industrial 2 of 5 barcodes are as follows:

-

Shipping and logistics:

Industrial 2 of 5 barcodes are used in shipping and logistics to track packages and shipments. These barcodes can be printed on shipping labels, making it easy for logistics personnel to scan and track packages as they move through the supply chain.

-

Warehouse management:

Industrial 2 of 5 barcodes are used in warehouse management systems to track the movement of goods within a warehouse. These barcodes are printed on labels attached to individual items, making it easy to track their location and movement.

-

Healthcare:

Industrial 2 of 5 barcodes are used in healthcare to track medical equipment and supplies. These barcodes can be used to track the location and movement of medical equipment, ensuring that it is available when needed and reducing the risk of loss or theft.

-

Retail:

Industrial 2 of 5 barcodes are used in retail to track the movement of goods through the supply chain. These barcodes can be used to track the movement of goods from suppliers to distribution centers, and from distribution centers to retail stores, ensuring that products are available when customers need them.

-

Manufacturing:

Industrial 2 of 5 barcodes are used in manufacturing to track the movement of goods and raw materials within a production facility. These barcodes can be used to track the movement of parts and components through the production process, ensuring that products are manufactured to the required specifications.

-

Automotive industry:

Industrial 2 of 5 barcodes are used in the automotive industry to track the movement of parts and components through the supply chain. These barcodes can be used to track the location of parts as they move from suppliers to assembly plants, ensuring that they are available when needed for production.

-

Inventory management:

Industrial 2 of 5 barcodes are extensively used in inventory management systems. These barcodes can hold a large amount of information in a small space, making them ideal for tracking inventory and stock levels.

Overall, Industrial 2 of 5 barcodes have a wide range of applications in various industries. These barcodes are easy to print and scan, making them an ideal choice for tracking inventory, shipments, and goods through the supply chain.

Structure of an Industrial 2 of 5 Barcode

Industrial 2 of 5 is a type of barcode commonly used in industrial applications for tracking and inventory management. It is a simple, linear barcode that encodes information in the width of the bars and spaces. In this response, I will explain the structure of an Industrial 2 of 5 barcode in detail, including its format, encoding, and error correction.

-

🞛

Format:

An Industrial 2 of 5 barcode consists of a series of bars and spaces arranged in a specific pattern. The pattern is based on a series of two narrow bars followed by three narrow spaces, with a wide space between each group of bars and spaces. Each bar and space in the barcode represents either a binary 0 or 1. The barcode can be of any length, but typically it contains 14 digits (or characters).

-

🞛

Encoding:

In an Industrial 2 of 5 barcode, the digits or characters are encoded using a combination of bars and spaces. Each digit is represented by a unique pattern of bars and spaces, with each pattern consisting of five elements (two bars and three spaces). The first bar in the pattern represents a binary 1, while the second bar represents a binary 0. The three spaces between the bars are used to separate the patterns.

To encode a digit, the appropriate pattern of bars and spaces is used. For example, the digit 0 is represented by the pattern “NNWWN” (where “N” represents a narrow space and “W” represents a wide space), while the digit 1 is represented by the pattern “WNWNN”. Each digit is encoded in this way, resulting in a unique pattern for each digit.

-

🞛

Error Correction:

Industrial 2 of 5 barcodes do not typically include any error correction or detection mechanisms. This means that if any part of the barcode is damaged or obscured, the data may not be readable. To reduce the risk of errors, the barcode should be printed or marked clearly and consistently, and should be scanned using a high-quality barcode scanner.

In summary, an Industrial 2 of 5 barcode is a simple, linear barcode used for tracking and inventory management in industrial applications. It consists of a series of bars and spaces arranged in a specific pattern, with each digit encoded using a unique pattern of bars and spaces. While there is no error correction or detection in an Industrial 2 of 5 barcode, the risk of errors can be reduced by printing or marking the barcode clearly and consistently, and using a high-quality barcode scanner to read it.

Difference Between Industrial 2 of 5 Barcode And Other Barcode Types

Industrial 2 of 5 barcode is a type of linear barcode that is used to encode numeric data. It is similar to other linear barcode types, such as Code 39 and Code 128, in that it uses a series of bars and spaces to represent data. However, there are several key differences that distinguish Industrial 2 of 5 barcode from other barcode types.

-

Data density:

Industrial 2 of 5 barcode has a higher data density than most other linear barcode types. This means that it can hold more information in a smaller space, making it ideal for applications where space is limited.

-

Character set:

Industrial 2 of 5 barcode is limited to encoding only numeric data, whereas other barcode types, such as Code 128, can encode a wider range of characters, including letters and special characters.

-

Encoding:

Industrial 2 of 5 barcode uses interleaved encoding, which means that pairs of characters are encoded together. This results in a higher data density than other barcode types, which typically use sequential encoding.

-

Checksum:

Industrial 2 of 5 barcode does not include a checksum by default, whereas other barcode types, such as Code 39 and Code 128, do include a checksum. This means that Industrial 2 of 5 barcode may be less reliable than other barcode types in detecting errors.

-

Length:

Industrial 2 of 5 barcode is typically shorter than other barcode types, such as Code 39 and Code 128. This is because it uses only two bars to represent each character, whereas other barcode types use more bars to represent each character.

-

Printing:

Industrial 2 of 5 barcode is typically printed at a lower resolution than other barcode types. This is because the bars and spaces are wider than in other barcode types, making it easier to print at lower resolutions without sacrificing readability.

Overall, Industrial 2 of 5 barcode is a specialized barcode type that is optimized for applications where space is limited and high data density is required. It is not as versatile as other barcode types, such as Code 39 and Code 128, but it is well-suited to certain types of applications, such as inventory management and shipping and logistics.