How do I print information on barcode labels

To print information on barcode labels, you can use barcode software that allows you to customize the label design and add text fields. Here are the general steps you can follow:

-

【1】Open your barcode software and select the barcode type you want to use.

-

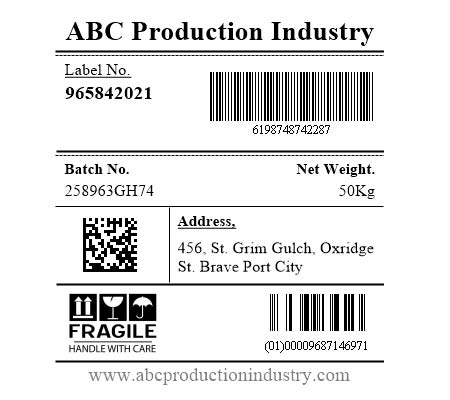

【2】Enter the information you want to print on the barcode label, such as product name, SKU, price, or other relevant details.

-

【3】Customize the label design, including the size, shape, and color of the label, as well as the font and size of the text fields.

-

【4】Add the barcode to the label design and adjust its position and size as necessary.

-

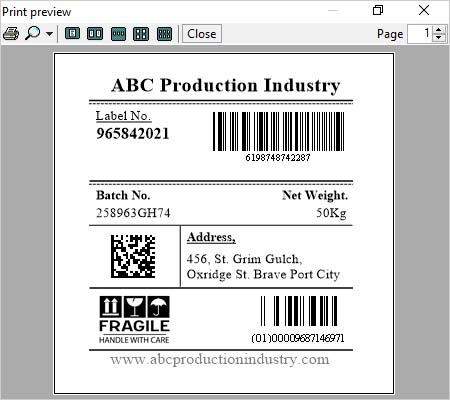

【5】 Preview the label to ensure it looks correct and all information is legible.

-

【6】 Connect your barcode printer to your computer and load it with appropriate barcode labels. Print the label using the barcode software.

-

【7】 Check the barcode label to ensure all information printed correctly and is scannable.

By printing information on barcode labels, you can provide more detailed information about your products or inventory items, making it easier to manage and track them. Additionally, printing information on barcode labels can help reduce errors in data entry and improve efficiency in inventory management and stock control.