Posted By: 👤 Digital Deeper

Last Updated On:

Scan Inventory Barcodes Software

To scan inventory barcodes, you will need a barcode scanner device that is compatible with the type of barcode used by your inventory system. Here are the steps you can follow:

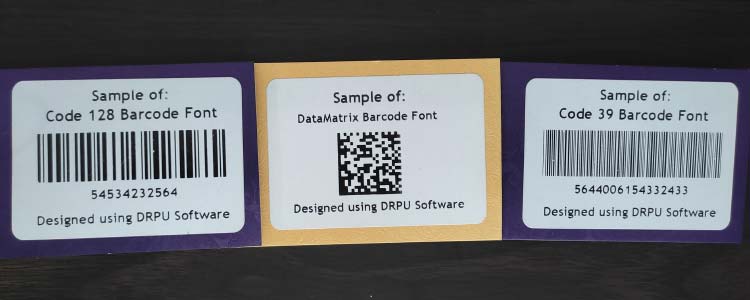

Step-1 Identify the type of barcode used by your inventory system. Common types include Code 39, Code 128, and Data Matrix.

Step-2 Purchase a barcode scanner device that is compatible with the type of barcode used by your inventory system. You can find barcode scanners online or at electronics stores.

Step-3 Connect the barcode scanner to your computer or mobile device using a USB or Bluetooth connection.

Step-4 Open your inventory software or app on your device.

Aim the barcode scanner at the barcode on the inventory item and press the trigger button on the scanner to scan the code.

Step-5 The barcode scanner will read the code and send the information to your inventory software or app, which will update the inventory count, location, and other relevant data.

Step-6 Verify that the inventory information displayed matches the item you are scanning and make any necessary adjustments to the inventory data.

Download and Install Inventory Management Barcodes Software

Additionally, scanning inventory barcodes can reduce the risk of human error in manually entering inventory data and improve the accuracy and speed of inventory counts and adjustments.

Choose Right Inventory Barcode Tools

When choosing the right barcode for your inventory, it is important to consider the type of inventory you have, the environment it will be used in, and your business needs. Here are some factors to consider:

- Barcode Type: There are different types of barcodes, including UPC, EAN, Code 39, and Code 128. The type of barcode you choose will depend on the type of inventory you have and the industry you are in.

- Barcode Size: The size of the barcode label should be appropriate for the item being labeled. Some items may require larger labels with bigger barcodes, while others may require smaller labels with smaller barcodes.

- Environment: The environment where the inventory will be stored and used should be considered when choosing a barcode. For example, if the inventory will be exposed to harsh conditions, you may need to use a more durable label and barcode.

- Compatibility: The barcode system you choose should be compatible with your inventory management software and hardware.

- Scalability: Consider whether the barcode system can grow with your business as your inventory grows.

- Budget: The cost of the barcode system should also be considered, including the cost of the barcode printer, labels, and software.

By considering these factors, you can choose the right barcode for your inventory that will meet your business needs and improve your inventory management processes.

Print Inventory Barcodes Software

To print inventory barcodes, you will need a barcode printer and appropriate barcode software. Here are the general steps you can follow:

[1] Choose the type of barcode you want to print. Common types of inventory barcodes include Code 39, Code 128, and QR codes.

[2] Create a unique identifier for each item you want to print a barcode for. This can be a serial number, SKU (Stock Keeping Unit), or other identifier.

[3]- Enter the identifier into your barcode software and select the barcode type you want to generate.

[4] Adjust the settings for the barcode, such as size, font, and orientation.

[5] Preview the barcode to ensure it looks correct.

[6] Connect your barcode printer to your computer and load it with appropriate barcode labels

[7] Print the barcode using the barcode software.

[8] Check the barcode label to ensure it printed correctly and is scannable.

By printing inventory barcodes, you can label your products and streamline your inventory management process. Additionally, printing barcodes can help reduce errors in product identification and tracking, resulting in more accurate inventory counts and better stock management.

Uses Of Inventory Barcodes Software

Using barcodes can significantly improve the accuracy of your inventory tracking system. Here are some steps you can take to ensure the accuracy of your inventory using barcodes:

- Create a barcode for each item: Make sure that every item in your inventory has a unique barcode assigned to it. This barcode should be scanned and recorded whenever the item is received, moved, or sold.

- Implement a barcode scanner: Use a barcode scanner to ensure that every item is scanned and recorded accurately. Make sure that your barcode scanner is calibrated properly and that your staff is trained to use it correctly.

- Update your inventory management system: Make sure that your inventory management system is updated in real-time whenever an item is scanned or moved. This will ensure that your inventory counts are always up-to-date.

- Set up alerts for low inventory levels: Use your inventory management system to set up alerts for low inventory levels. This will help you order new inventory before you run out of stock.

By following these steps, you can ensure the accuracy of your inventory using barcodes. This will help you make informed business decisions and improve the overall efficiency of your operations. .

Create Inventory Control Barcodes Softawre

To create inventory control barcodes, follow these steps:

- Choose a barcode type: The most common barcode types for inventory control are Code 39, Code 128, and EAN-13. Choose the one that best fits your needs.

- Obtain a barcode generator software: You can use online barcode generators or purchase barcode generator software that allows you to customize the barcode with your desired data.

- Enter the data: Input the data you want to encode in the barcode into the software. This may include product IDs, SKUs, and other relevant information.

- Customize the barcode: You can customize the barcode by adjusting the size, color, and font to your liking.It is scannable and accurately encoded with the correct information.

- Generate the barcode: Once you've input all the necessary data and customized the barcode, generate it in the desired file format, such as JPEG, PNG, or PDF.

- Print the barcode: Print the barcode on a label or product packaging using a barcode printer. Make sure the barcode is printed at the appropriate size and quality to ensure accurate scanning.

By following these steps, you can ensure that your inventory control barcodes are accurate and readable, which can improve the accuracy of your inventory tracking and reduce errors in your operations.

Ensure Accuracy of Inventory Control Barcodes

To ensure the accuracy of inventory control barcodes, you can follow these steps:

- Use high-quality barcode labels: Make sure that the barcode labels you use are high-quality and can withstand normal wear and tear. Low-quality labels can become unreadable over time, which can lead to errors in your inventory tracking.

- Print barcodes with sufficient contrast: When printing barcodes, ensure that there is sufficient contrast between the barcode and the background. This will make it easier for barcode scanners to read the barcode accurately.

- Verify barcode readability: Before using barcode labels, verify that the barcode is readable by scanning it with a barcode scanner. If the barcode is not readable, reprint the label or use a different label.

- Train staff on proper barcode usage: Train your staff on the proper usage of barcode scanners and labels to ensure that they are being used correctly.

- Conduct regular barcode audits: Conduct regular audits of your inventory control barcodes to ensure that they are still readable and accurate. This can help prevent errors in your inventory tracking.

By following these steps, you can ensure that your inventory control barcodes are accurate and readable, which can improve the accuracy of your inventory tracking and reduce errors in your operations.