Different Types of Inventory Barcodes

-

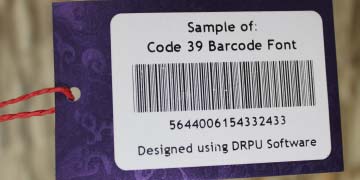

Code 39:

Code 39 barcodes are commonly used for inventory tracking and asset management. They can encode alphanumeric characters and are relatively easy to read with a barcode scanner.

-

Interleaved 2 of 5:

Interleaved 2 of 5 barcodes are commonly used in the logistics and transportation industries to track packages and shipments. They can encode only numbers and are often used for bulk inventory tracking.

-

QR Code:

QR codes are a type of 2D barcode that can be used to track inventory and assets. They can encode a large amount of data, including text, URLs, and other information, and can be read by smartphones and other mobile devices.

-

Data Matrix:

Data Matrix barcodes are also a type of 2D barcode that can be used for inventory tracking and asset management. They can encode a large amount of data, including text, numbers, and symbols, and can be read by a variety of scanning devices.

Barcodes used for Inventory Control :-

There are several types of barcodes commonly used for inventory control, including the Universal Product Code (UPC), the Code 39, and the Code 128:

- The UPC is a widely recognized barcode system used to identify products in retail stores, but it can also be used for inventory control. Each UPC barcode includes a unique 12-digit number that identifies the product, and this number can be used to track inventory levels and monitor product movement.

- The Code 39 is a type of barcode that encodes alphanumeric characters, including letters, numbers, and symbols. It is commonly used for inventory control in manufacturing and distribution industries because it can be easily customized to include specific information such as lot numbers and expiration dates

- The Code 128 is another type of barcode commonly used for inventory control. It can encode a wide range of characters, including letters, numbers, and symbols, and it is designed to be highly flexible and customizable. Code 128 barcodes can also include checksum digits to ensure accuracy and help prevent errors during scanning.

Other types of barcodes that may be used for inventory control include the Interleaved 2 of 5 (ITF) barcode, which is commonly used in the distribution industry, and the Data Matrix barcode, which can encode large amounts of data in a small space and is often used for tracking small items.

Overall, the type of barcode used for inventory tracking and asset management will depend on the specific application and the amount of data that needs to be encoded. Code 39 and Code 128 are common choices for general inventory tracking, while Interleaved 2 of 5 is often used for bulk inventory tracking. QR codes and Data Matrix codes are commonly used for tracking assets and equipment.

Download Inventory Barcode Software Here!

Benefits of using Inventory Barcodes

Inventory barcodes offer several benefits to businesses, including:

-

Increased efficiency:

Barcode scanning technology enables businesses to automate their inventory control processes, which improves accuracy and speeds up inventory tracking and management. This saves time and reduces labour costs. Scanning barcodes is a faster process than manual entry, allowing for faster inventory counts and replenishment.

-

Improved accuracy:

Barcode scanning eliminates human error, ensuring that the inventory data captured is accurate and reliable.Barcode scanning eliminates the possibility of manual errors, improving the accuracy of inventory management.

-

Cost savings:

Barcode scanning technology reduces the need for manual data entry and paper-based record-keeping, which reduces the risk of errors and saves time and money.

-

Improved customer service:

With accurate inventory tracking, businesses can ensure that they always have the products their customers need in stock, which improves customer satisfaction and loyalty.

-

Reduced labour costs:

Barcode scanning reduces the need for manual labour in inventory management, reducing labor costs.

Overall, inventory barcodes can help businesses improve efficiency, accuracy, and customer service, while reducing costs and improving inventory management.

Working of Inventory Barcode

Inventory control barcodes work by assigning a unique code to each inventory item, which is then printed on a label and affixed to the item or its packaging. The barcode can be scanned using a barcode scanner to quickly and accurately identify the item and its associated information, such as quantity, location, and cost. This information is then recorded in an inventory management system, allowing businesses to track inventory levels, monitor stock movements, and manage orders and shipments. Barcode technology can help to streamline inventory management, reduce errors, and improve overall efficiency

Some Major Points:

- An inventory barcode works by encoding information about a product, such as its unique identifier, in a scannable barcode format that can be read by a barcode scanner. When the barcode is scanned, the information it contains is transmitted to an inventory management system or database, which can be used to track the product's location, quantity, and other relevant information.

- When the barcode is scanned, the scanner reads the pattern of bars and spaces in the barcode, decodes the information it contains, and transmits it to the inventory management system or database. This allows inventory managers to quickly and accurately track products as they move through the supply chain, from receiving and storage to shipping and sales.

- Inventory barcodes can help to streamline inventory management, reduce errors and inaccuracies, and improve efficiency in warehouse and retail settings. They are widely used in a variety of industries, including retail, healthcare, manufacturing, logistics.

- To create an inventory barcode, the product information is first encoded in a barcode format using a software tool or online barcode generator. The barcode is then printed on a label or directly onto the product packaging using a barcode printer.

Troubleshooting Your Inventory Barcodes

If you are experiencing issues with inventory barcodes, here are some steps you can take to troubleshoot the problem:

-

Check The Barcode:

Make sure the barcode is clean and not damaged. If the barcode is smudged, scratched, or torn, it may not be readable by the scanner.

-

Check The Scanner:

Ensure the scanner is properly connected to the computer or inventory management system and that it is powered on. If the scanner is not functioning, check the cables and power source.

-

Check The Barcode Format:

Make sure the barcode format is compatible with the scanner. Some scanners are not able to read certain barcode formats.

-

Check The Scanner Settings:

Verify that the scanner is configured with the correct settings for your inventory management system, including the correct barcode format and any additional features you require.

-

Test The Scanner:

Test the scanner by scanning different barcodes to ensure it is functioning properly.

-

Check The Inventory Management Software:

Verify that the software you are using to manage inventory is configured correctly and is compatible with the scanner.

-

Check The Database:

Verify that the barcode information is properly stored in the database and that the database is functioning properly.

-

Update The Barcode or Scanner:

If the barcode or scanner is outdated, consider updating to a newer version that is compatible with your inventory management system.

-

Contact Support:

If you have tried all of the above steps and are still experiencing issues, contact the scanner or software provider's support team for further assistance.

By following these troubleshooting steps, you can identify and resolve any issues with inventory barcodes, ensuring that your inventory management processes run smoothly and efficiently.

| Updated on:06/April/2023