How can I ensure that my ID Badge is durable and long-lasting

To ensure that your ID badge is durable and long-lasting, there are several steps you can take. Here are some detailed guidelines:

-

Safe Storage:

Proper storage is crucial when the ID badge is not in use. Keep it in a secure place, such as a cardholder or a protective sleeve, to prevent bending, scratching, or accidental damage. Avoid exposing the badge to extreme temperatures or prolonged sunlight, as this can cause fading or warping.

-

Protective Coating:

Student ID badges often serve as security credentials, so it's important to consider features that enhance their security. software that supports holographic overlays, watermarking, etc. Consider whether software supports encoding and printing of smart cards for access control systems.

-

Reinforced Edges:

The edges of the ID badge are prone to fraying or peeling over time. To reinforce them, you can opt for rounded corners or use edge sealants. Rounded corners minimize the likelihood of corner damage, while edge sealants create a protective barrier that prevents the layers of the badge from separating.

-

Wearable Accessories:

Consider using additional wearable accessories to protect your ID badge from damage caused by regular use. Badge holders, badge reels, or lanyards can help keep your ID badge securely attached and reduce the chances of accidental drops or loss. Choose accessories made of sturdy materials, such as nylon or metal, for increased durability.

-

Quality Printing:

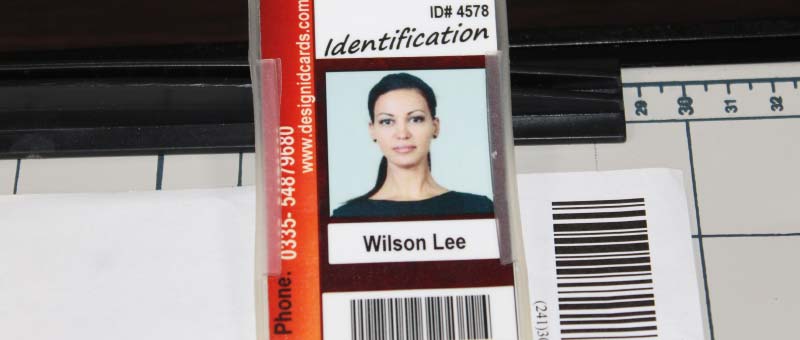

Ensure that the printing on your ID badge is of high quality. The text, images, and any barcodes or QR codes should be printed clearly and legibly. Professional-grade printers or printing services can produce sharper and more durable prints. Additionally, consider using dye-sublimation or thermal transfer printing methods, as they provide better resistance to fading and smudging.

-

Material Selection:

Choose a high-quality material for your ID badge. Common options include PVC (polyvinyl chloride), polycarbonate, or laminated paper. PVC and polycarbonate are more durable and resistant to wear and tear. They are also water-resistant, which can be beneficial in case of accidental spills or exposure to moisture.

-

Encoding Techniques:

If your ID badge contains embedded technology, such as RFID or magnetic stripes, proper encoding is crucial for longevity. Use reliable encoding techniques to ensure that the embedded technology functions correctly for an extended period. This may involve following specific encoding standards and protocols provided by the technology manufacturer.

-

Regular Maintenance:

Perform regular maintenance to prolong the life of your ID badge. This includes cleaning the badge with a soft cloth or mild cleaning solution to remove dirt, oils, or debris. Avoid using harsh chemicals or abrasive materials that could damage the badge's surface or printed information. If the badge gets wet, gently dry it to prevent water damage.

By following these steps, you can significantly enhance the durability and longevity of your ID badge, ensuring it remains in good condition for an extended period.

Printing Options Available for ID Badges Design

There are several printing options available for ID badges, each with its own benefits and considerations. Here are the most common printing methods used for ID badges, explained in detail:

-

➲ Direct-to-Card (DTC) Printing:

Direct-to-card printing, also known as dye-sublimation printing, is a popular method for ID badge printing. Design is printed directly onto the surface of card. Printers use a ribbons contains solid dyes, which are transferred onto the card's surface, creating a vibrant and durable print.

Benefits:• Excellent print quality with sharp details, gradients, and vibrant colors.

• Capable of printing edge-to-edge, covering the entire card surface.

• Durable and resistant to fading, smudging, and scratching.

• Suitable for printing photos and complex designs.

Considerations:➨ Not ideal for printing on textured or non-smooth card surfaces.

➨ Printing speed may be slower compared to other methods.

➨ Limited color options as the dye ribbons come in specific color panels.

-

➲ Reverse Transfer

Printing:

Reverse transfer printing, also known as retransfer printing, is another common method used for ID badges. It involves printing the design onto a transparent film, which is then thermally bonded to the card's surface using heat and pressure. The process creates a durable and high-quality print.

Benefits:• High print quality with sharp details, including fine lines and small text.

• Capable of printing on various card surfaces, including textured cards.

• Excellent color reproduction and color vibrancy.

• Offers over-the-edge printing, covering the entire card surface.

Considerations:➨ Slower printing speed compared to direct-to-card printing.

➨ Requires specialized equipment and consumables.

➨ Can be costlier due to the additional transfer film and consumables.

-

➲ Thermal Printing:

Thermal printing is a widely used method for printing simple text, barcodes, and basic designs on ID badges. This method utilizes heat-sensitive ribbons that transfer the desired image onto the card's surface when heated by the print head. Thermal printing is often used for printing variable information, such as employee names or badge numbers, on pre-printed cards.

Benefits:• Fast and efficient printing method.

• Suitable for printing variable information.

• Can be used for monochrome or single-color printing.

• Relatively cost-effective.

Considerations:➨ Limited color options (typically monochrome or single-color printing).

➨ Lower print resolution compared to other methods.

➨ Not ideal for complex designs or images.

-

➲ Inkjet Printing:

Inkjet printing is a versatile method that utilizes inkjet technology to print ID badges. It involves ejecting tiny droplets of ink onto the card's surface, forming the desired design. Inkjet printing is commonly used for on-demand and low-volume badge printing.

Benefits:• Offers flexibility and on-demand printing capabilities.

• Can print variable information, text, and basic designs.

• Suitable for low-volume printing needs.

• Cost-effective for small-scale operations.

Considerations:➨ Lower print quality compared to other methods.

➨ Susceptible to smudging and fading if not adequately protected.

➨ Limited durability compared to other printing methods.

➨ Slower printing speed for high-resolution prints.

When choosing the printing option for your ID badges, For simple text and basic designs with cost-efficiency in mind, thermal printing or inkjet printing may be suitable options.

Can I add security features to my ID Badge design

Yes, you can certainly add security features to your ID badge design to enhance its security and prevent unauthorized use or counterfeiting. Here are several common security features you can consider incorporating into your ID badge design:

-

Holograms:

Holographic elements, such as holographic foils or patches, can be added to the ID badge design. These elements are difficult to replicate and provide a visually striking feature that is challenging to counterfeit.

-

UV (Ultraviolet) Printing:

UV inks can be used to print specific details on the ID badge that are only visible under ultraviolet light. This feature helps verify the authenticity of the badge and makes it harder to duplicate.

-

Microprinting:

Fine lines of text or images can be printed using microscopic fonts or patterns that are difficult to reproduce accurately. Microprinting is often used for security purposes, as it becomes blurred or illegible when copied or scanned.

-

Guilloche Patterns:

Intricate, decorative patterns known as guilloche patterns can be added to the design. These patterns are difficult to reproduce accurately and are commonly used on banknotes and official documents for security purposes.

-

Embedded Security Elements:

Embedding security elements into the ID badge, such as holographic strips, embedded chips, or RFID tags, can provide additional layers of security. These elements can store and transmit information that can be verified by authorized devices or personnel.

-

Tamper-Evident Features:

Include tamper-evident elements, such as holographic seals, that indicate if the ID badge has been tampered with or removed from its original position. These features can make it apparent if someone attempts to alter or counterfeit the badge.

-

Variable Data Printing:

Personalize each ID badge by using variable data printing, which allows for unique information, such as employee names, photos, or identification numbers, to be printed on each badge. This makes it harder to duplicate or use counterfeit badges.

-

Barcodes or QR Codes:

Include barcodes or QR codes on the ID badge that can be scanned for verification purposes. These codes can contain encrypted information or links to a secure database for instant identification and authentication.

-

Lamination and Custom Materials:

Use high-quality lamination or custom materials that make the ID badge more durable and resistant to tampering or forgery attempts. Special materials may have unique visual or tactile characteristics that are challenging to replicate.

-

Visible and Hidden Security Features:

Incorporate both overt (visible) and covert (hidden) security features into the design. Visible features act as a deterrent, while hidden features can only be identified using specialized tools or knowledge.

It's important to note that the complexity and effectiveness of these security features may vary, and some advanced counterfeiters may still find ways to replicate them. It is recommended to consult with security experts or printing professionals who specialize in ID badge design to ensure the best combination of features for your specific security requirements.