Information about Industrial Barcodes

Industrial barcodes are barcodes that are designed and used in industrial settings, such as manufacturing, logistics, and distribution. These barcodes are typically more durable and rugged than other types of barcodes, and they are capable of withstanding harsh industrial environments. Industrial barcodes are machine-readable codes used to identify and track products, equipment, and materials in various industrial settings. They are typically used to improve operational efficiency and inventory management by automating the data collection process.

Industrial barcodes are used in a wide range of industries, including automotive, aerospace, healthcare, food and beverage, and more.

Benefits Of Industrial Barcode:

The benefits of implementing an industrial barcode system can include increased efficiency and accuracy in inventory management, production processes, and asset tracking. With a barcode system in place, industrial facilities can quickly and easily scan items, reducing the likelihood of errors and saving time. The system can also provide real-time tracking information that can help optimize production processes, reduce waste and losses, and improve supply chain visibility.

Additionally, a barcode system can improve safety by ensuring that the right materials are used in production processes, and by providing real-time tracking of hazardous materials and equipment. This can help reduce the risk of accidents and injuries in the workplace, improving employee safety and reducing costs associated with workplace accidents.

Different Types Of Industrial Barcodes

There are many types of industrial barcodes, including:

-

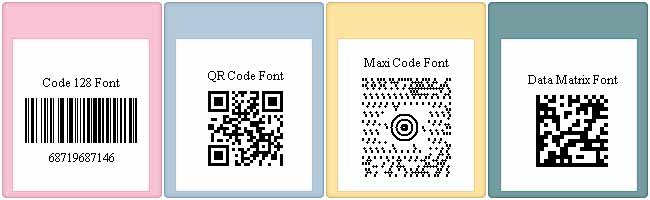

Code 128:

This is a high-density linear barcode that can encode large amounts of data and is commonly used in logistics and inventory management.

-

Data Matrix:

This is a 2D barcode that can encode a lot of data in a small space and is commonly used in electronics manufacturing.

-

QR code:

This is a 2D barcode that can store a large amount of data, including text, URLs, and other information, and is commonly used in marketing and advertising.

-

Maxi Code:

This is a 2D barcode that is commonly used in transportation and logistics applications to encode information about shipments and packages.

Barcode Software used by Different Industries:

There are numerous industries that commonly use barcode software for Windows. Here are a few examples:

-

Government:

Government agencies use barcode software for Windows to manage inventory, automate supply chain processes, and track assets.

-

Education:

Educational institutions use barcode software for Windows to track assets, manage library inventory, and automate attendance tracking.

-

Manufacturing:

Manufacturers use barcode software for Windows to track inventory, automate production processes, and manage shipping and receiving.

-

Retail:

Retailers use barcode software for Windows to create and print barcode labels for products, manage inventory, and automate the checkout process.

-

Hospitality:

Hotels and restaurants use barcode software for Windows to manage inventory, automate ordering processes, and track customer orders and payments.

-

Healthcare:

Healthcare providers use barcode software for Windows to manage patient records, track medications, and automate laboratory testing and blood transfusions.

-

Logistics and Warehousing:

Logistics companies and warehouses use barcode software for Windows to manage inventory, automate shipping and receiving processes, and fulfill orders.

Overall, barcode software for Windows is used in various industries to improve efficiency, accuracy, and productivity. It helps businesses and organizations to streamline their operations and reduce errors, ultimately leading to cost savings and improved customer satisfaction.

In industrial settings, barcodes are used for a wide range of products and processes, including:

-

Manufacturing:

Barcodes are used to track raw materials, work-in-progress, and finished goods in the manufacturing process. This enables manufacturers to maintain accurate inventory levels and reduce production costs.

-

Logistics:

Barcodes are used to track and manage the movement of goods throughout the supply chain, from the manufacturer to the end consumer. This enables companies to optimize their logistics and reduce shipping errors.

-

Maintenance and repair:

Barcodes are used to track and manage equipment maintenance and repair schedules, ensuring that equipment is serviced and repaired on time to minimize downtime and maximize productivity.

-

Asset management:

Barcodes are used to track and manage the location and usage of equipment and materials, allowing companies to optimize their asset utilization and reduce losses due to theft or misplacement.

Overall, industrial barcodes are used to improve efficiency, reduce errors, and enhance overall productivity in a wide range of industrial settings.