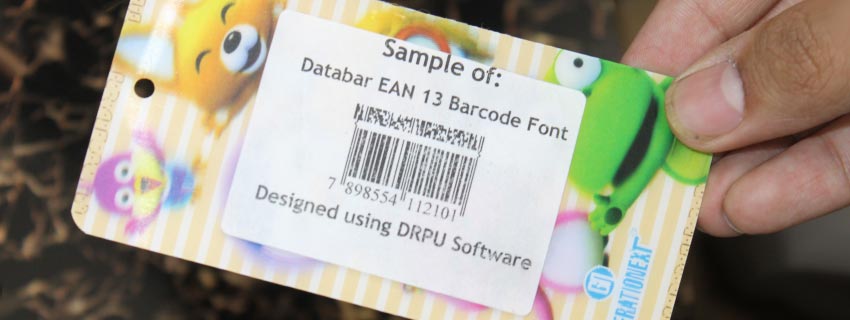

Information Encoding in a Databar EAN 13 Barcode

The Databar EAN-13 barcode can encode a variety of information, including product identification codes, pricing information, and promotional offers. Here is a more detailed explanation of the information that can be encoded in a Databar EAN-13 barcode:

-

Product Identification

The Databar EAN-13 barcode encodes a 13-digit code that includes a country code, manufacturer code, and product code. The country code is a three-digit code that identifies the country, while the manufacturer code is a five-digit code that identifies the specific manufacturer of the product. The product code is a unique five-digit code that identifies the specific product.

-

Pricing Information:

In addition to product identification codes, Databar EAN-13 barcodes can also encode pricing information. This allows retailers to quickly and easily update pricing information, which can help to improve pricing accuracy and reduce errors. The pricing information can be encoded in a variety of formats, including currency symbols, decimal points, and even fractions.

-

Promotional Offers:

Databar EAN-13 barcodes can also be used to encode several promotional offers, such as discounts, coupons or buy-one-get-one-free (BOGO) offers. This allows retailers to automatically apply discounts at the point of sale, which can help to improve sales and customer satisfaction.

-

Expiration Dates:

In some cases, Databar EAN-13 barcodes may also be used to encode expiration dates for perishable products, such as food, drinks, or medicine. This allows retailers to ensure that products or items are sold before they expire, which can help to reduce waste and improve customer safety.

-

Batch and Lot Numbers:

Databar EAN-13 barcodes can also be used to encode batch and lot numbers, which are important for tracking products and identifying issues. By scanning barcodes in the supply chain, businesses can track which batch or lot a product came from, which can help to identify and address quality control issues.

-

Serial Numbers:

Finally, Databar EAN-13 barcodes can also be used to encode serial numbers, which are unique identifiers for individual products. Serial numbers are often used for high-value products such as electronics or jewelry, as they allow retailers to track individual products or items and deter theft.

Overall, the Databar EAN-13 barcode can encode a wide range of information, including product identification codes, pricing information, promotional offers, expiration dates, batch and lot numbers, and serial numbers. This makes it a versatile tool for businesses in a variety of industries, from retail to healthcare to manufacturing.

Usage of Databar EAN 13 Barcodes in Different Industries

Databar EAN-13 barcodes are widely used in a variety of industries due to their versatility and compatibility with existing systems. Here are some of the industries that commonly use Databar EAN-13 barcodes:

-

Retail:

Retail is perhaps the most common industry for Databar EAN-13 barcodes. These barcodes are used to identify and track products, manage inventory, and facilitate sales transactions. Retailers use barcodes to streamline operations, improve efficiency, and reduce errors. With the use of Databar EAN-13 barcodes, retailers can scan products at the point of sale, automatically update pricing information, and track inventory levels in real-time.

-

Healthcare:

Healthcare is another industry where Databar EAN-13 barcodes are widely used. These barcodes are used to track medications, medical devices, and other healthcare products throughout the supply chain. By scanning barcodes at various points along the supply chain, healthcare providers can ensure that products are safe and effective, and can track products in case of recalls.

-

Manufacturing:

In the manufacturing industry, Databar EAN-13 barcodes are used to track raw materials, work-in-progress, and finished goods. These barcodes can be used to track products throughout the entire manufacturing process, from assembly to shipping. By scanning barcodes at various stages of production, manufacturers can identify bottlenecks, track production rates, and ensure that products are assembled correctly.

-

Food and Beverage:

In the food and beverage industry, Databar EAN-13 barcodes are used to track ingredients, manage inventory, and ensure compliance with food safety regulations. These barcodes are also used to track products through the supply chain, from production to distribution to retail. By scanning barcodes at each step of the process, food and beverage companies can ensure that products are safe, fresh, and meet quality standards.

-

Logistics and Transportation:

The logistics and transportation industry relies on Databar EAN-13 barcodes to track shipments, manage inventory, and ensure timely delivery of goods. These barcodes are used to identify packages and shipments, track them through the supply chain, and ensure that they are delivered to the correct location on time.

-

Government:

In the government sector, Databar EAN-13 barcodes are used to track assets and inventory, manage logistics, and ensure compliance with regulations. Government agencies use barcodes to track equipment and supplies, manage inventory levels, and ensure that assets are properly maintained and used.

Overall, Databar EAN-13 barcodes are used in a wide range of industries, from retail to healthcare to government. These barcodes provide a simple, effective way to track products and manage inventory, while also ensuring compliance with regulations and improving efficiency.