Is it better to use Roll Labels over Sheet Labels?

By: Digital Deeper

| 31/08/2022

Both barcode labels and stickers consist of a sticky backing called adhesive that is applied to a material, usually paper, where colors or graphics are printed. Physically speaking, there isn't much difference between a label and a sticker. However, there are subtle differences between the two classifications. By definition, a label is a little piece of paper, plastic, or other similar material that is affixed to an item and contains information about it.

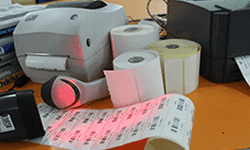

What are Roll Labels?

Roll labels, to repeat the obvious once again, come on a roll. In essence, roll labels are wound around a piece of cardboard in a reel. They are among the greatest ways to buy barcode labels in large quantities. On them, specific label printers such as thermal transfer printers, direct thermal printers, and ink roll printers are used to print. Roll labelling is an inexpensive way to print barcode labels internally. It prints significantly more quickly, enabling shorter manufacturing runs. Roll labelling further enables automated application, which improves productivity and cuts down on time.

What are Sheet Labels?

Laser and inkjet printers can create sheet barcode labels, which are available in several paper sizes. You may purchase sheet labels in a variety of materials, including waterproof and gloss white. To meet everyone's demands, sheet labels come in a range of colours. Among other things, sheet labels can be used as mailing labels and address labels.

Simply defined, sheet labels are printed on a flat sheet, enabling for on-demand sheet printing of labels. When printing a single sheet at a time, certain printers can offer lesser numbers of labels, which can be a more cost-effective choice for people who just need to print a few labels each day.

Difference between Roll Barcode Labels and Sheet Labels

- ⇉Labels with various properties: Despite being intended to be applied to the same product, certain labels may demand that each barcode label have a separate set of data. Name tags, barcodes, and shipping labels are a few examples of projects. It is preferable to utilise roll labels in this situation. Since each label is distinct, it is simple to change the information, and printing on a roll printer is quicker and easier.

- ⇉Same details on different Labels: It makes sense to print barcode on label sheets since return barcode labels often carry the same information on each one. You may print as many labels in a very short period of time by simply filling a label sheet with duplicate designs.

- ⇉To make labels live longer: By melting a ribbon on a surface to form a barcode that is not altered by heat or light, thermal transfer printers produce a bar sequence on a label. These labels are best used for asset labelling and product identification since they can tolerate chemical interaction. Roll labels are necessary in this situation since they may be printed on with thermal transfer printers.

When should you use roll labels?

Roll labels are a cost-effective solution to buy large quantities of labels or stickers. Businesses that require longer runs and spend more on their barcode labels are quite fond of them.

For printing labels in bulk:

Roll labels are a better option than cut-to-size labels if you need to barcode large numbers of items. Labels often need to be on a roll in order to be used with labelling machines, which speed up the process. Compared to labelling by hand, automated labeling machines make it faster.

When there is a small storage:

Roll labels may be stored easily because they are already coiled up in a tube. Additionally, since each label is carefully stored in the ribbon until it is unfurled for use; there is no chance of unintended tears or folds. Roll labels have a distinctive feature that makes your desk more space-efficient, which is especially useful in tiny work spaces.

Automated Barcode Labeling:

Roll labels are the norm for labelling equipment, as was already indicated. However, you might still wish to buy the roll format if you plan to attach labels by hand. These labels are simpler to take off because of the backing. While putting individual labels to your items, the roll also holds them in place.

When should you use sheet labels?

Sheet labels are a great solution for particular circumstances as well as small enterprises that are just getting started.

- Test out sample labels:Sheet labels are a simple, cost-effective solution to test out a new brand, design, or barcode quality for your items. Try out various combinations of colours, typefaces, shapes, and materials. In addition packaging barcodes and shipping barcodes are print on sheet labels.

- Labels for limited time:Sheet barcode labels are also excellent for items that are in season. Sheet labels could be the best option if you simply need a limited run. If you have items that constantly alter their contents, rules, or other information included in QR Code, sheet labels can be an excellent option.

- Time Efficient:If you utilise a label supplier that allows you to store designs, printable blank sheet labels let you rapidly buy and print off labels as needed, which is quite helpful. With stored label designs and templates, you can print high-quality labels quickly if you're under time pressure.