Printing a Code 128 barcode can be done using various methods and technologies, ranging from desktop printers to high-volume industrial printers. The method used depends on the specific requirements of the application, including the size and type of barcode required, the printing volume, and the level of durability required.

CODE-128 Barcode: Printing, Scanning and Implementing

By: Techsavvy

Published: 2023-May-02

Printing of a Code-128 Barcode

Here are some general steps to follow when printing a Code 128 barcode:

-

Choose the appropriate printing technology:

The next step is to choose the appropriate printing technology for the specific application. There are various printing technologies available for printing Code 128 barcodes, including thermal transfer printing, direct thermal printing, and inkjet printing. The printing technology used depends on the specific application requirements, such as durability, speed, and volume.

-

Choose the appropriate barcode software:

The first step in printing a Code 128 barcode is selecting the appropriate barcode software. Barcode software is used to create and generate the barcode image. There are various barcode software options available in the market, both free and paid. Some popular options include BarTender, NiceLabel, and Labeljoy.

-

Enter the barcode data:

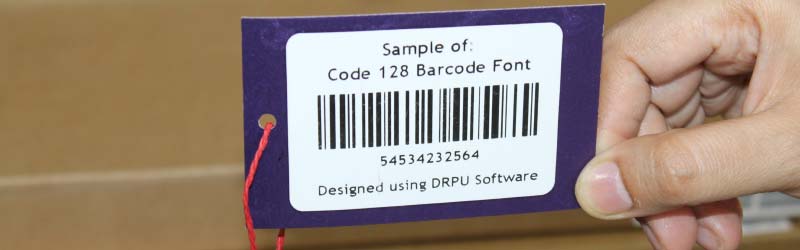

After selecting the barcode software, the next step is to enter the barcode data. Code 128 can encode a variety of characters, including uppercase letters, lowercase letters, numbers, and special characters. The software will generate the barcode image based on the entered data and the specific configuration settings.

-

Select the barcode size and format:

Code 128 barcodes can be generated in various sizes and formats, depending on the specific requirements of the application. The barcode size can be adjusted in the software, and the format can be selected based on the printing technology being used.

-

Print the barcode:

Once the printing settings have been tested and adjusted, the barcode can be printed. Depending on the printing technology being used, the barcode may need to be printed on a specific type of label or substrate to ensure durability and readability.

-

Test and adjust the printing settings:

Once the barcode has been created, it is important to test and adjust the printing settings to ensure that the barcode is printed correctly. This involves testing the size, contrast, and print quality of the barcode image.

Overall, the process of printing a Code 128 barcode involves selecting the appropriate barcode software, entering the barcode data, selecting the appropriate barcode size and format, choosing the appropriate printing technology, testing and adjusting the printing settings, and finally printing the barcode.

- ➔Code 128 barcode can be used internationally. The barcode standard is widely recognized and accepted across the world, making it a popular choice for a variety of applications in different countries.

- ➔Code 128 is also highly reliable and accurate, with a low error rate, which is important in applications where accuracy is critical, such as in healthcare or pharmaceuticals.

- ➔Code 128 is that it has a high density, meaning that it can store a large amount of data in a relatively small space. This makes it ideal for applications where space is limited, such as small product labels or packaging.

- ➔One of the reasons why Code 128 is widely used internationally is because it supports a large number of characters, including all ASCII characters. This means that it can be used to encode information in many different languages, making it a versatile option for businesses and organizations with a global presence.

- ➔Code 128 can be used to encode both numeric and alphanumeric data, making it suitable for a wide range of applications, including inventory management, logistics, and retail. It can also be used to encode variable data lengths, which makes it ideal for applications where the length of the encoded data may vary.

Scanning of a CODE-128 Barcode

Scanning a Code 128 barcode is a simple process that involves using a barcode scanner to read the barcode and decode the information stored within it. Here is a step-by-step guide on how to scan a Code 128 barcode:

- Scan the barcode: Aim the scanner at the Code 128 barcode and align the aiming pattern with the barcode. Hold the scanner steady until the barcode is successfully scanned.

- Position the barcode: Position the barcode in front of the scanner. The barcode scanner should be held steady and at a moderate distance from the barcode to ensure accurate scanning.

- Activate the scanner: Activate the scanner by pressing the trigger or scanning button. If using a mobile device, open the barcode scanning application and position the camera over the barcode.

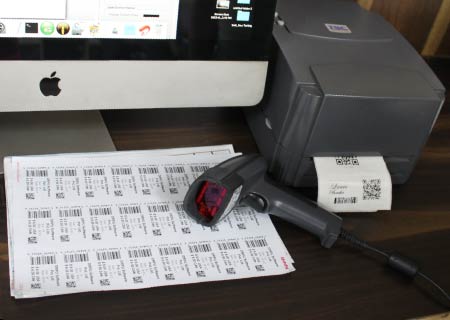

- Obtain a compatible barcode scanner: A barcode scanner is required to scan a Code 128 barcode. There are several types of barcode scanners available, including handheld, fixed-position, and mobile devices.

- Decode the information: Once the barcode is scanned, the scanner will decode the information stored within it. The decoded information can be displayed on the scanner or sent to a computer or mobile device via a wireless or wired connection.

- Verify the information: Verify the information decoded from the Code 128 barcode to ensure it matches the intended data. If the information is incorrect, the barcode may need to be scanned again or the source data may need to be updated.

- Use the decoded information: Once the information is verified, it can be used for various purposes, such as inventory tracking, product identification, and data collection.

In summary, scanning a Code 128 barcode is a straightforward process that requires a compatible barcode scanner and proper alignment of the barcode with the scanner. With accurate scanning, the information stored within the barcode can be quickly decoded and used for various applications.

Different types of devices read by Code-128 Barcode

Code 128 is one of the most widely used barcode types, and it is supported by a wide range of devices. In general, any device that can read standard linear barcodes should be able to read Code 128 barcodes. This includes barcode scanners, mobile devices with built-in cameras, and other image capture devices.

Mobile devices with built-in cameras have also become popular for reading barcodes, including Code 128 barcodes. There are many apps available for smart phones and tablets that can scan and decode barcodes, and many mobile operating systems also include built-in barcode scanning functionality.

Barcode scanners are the most commonly used device for reading Code 128 barcodes. These scanners can be handheld or stationary and come in a variety of forms. The most basic type of barcode scanner is a pen wand, which is a simple handheld device that is passed over the barcode to scan it. More advanced barcode scanners use laser or image-based technology to read barcodes more quickly and accurately.

In addition to traditional barcode scanners and mobile devices, there are also specialized devices designed for specific applications. For example, some point-of-sale systems include built-in barcode scanners, and some medical devices use barcode scanning to track patient information.

Overall, the wide range of devices that support Code 128 barcodes makes it a versatile and widely adopted barcode type that can be used in many different applications.

Cost Implementation of Code-128 Barcode

The cost of implementing a Code 128 barcode system can vary depending on the specific needs and requirements of the organization or business. There are several factors that can impact the overall cost, including the hardware and software required, the number of barcode labels or tags needed, and any additional services or support required.

-

Hardware Costs:

One of the primary costs associated with implementing a Code 128 barcode system is the hardware required to generate and read the barcodes. This can include barcode scanners, printers, and mobile devices that can read and generate barcodes. The cost of these devices can vary widely, depending on the features, capabilities, and brand.

-

Software Costs:

In addition to the hardware required, implementing a Code 128 barcode system also involves the purchase of software for generating and managing barcodes. The cost of this software can vary depending on the features and capabilities required.

-

Barcode Printer:

Barcode printers are used to generate the Code 128 barcode labels or tags. There are several types of barcode printers available, including desktop printers, mobile printers, and industrial printers. The cost of a basic desktop barcode printer can range from $200 to $500, while more advanced industrial-grade models can cost upwards of $2000.

-

Barcode Scanner:

Barcode scanners are essential for reading and decoding the information stored in the Code 128 barcode. There are several types of barcode scanners available, including handheld, wireless, and fixed-position scanners. The cost of a basic handheld scanner can range from $20 to $500, while more advanced models with additional features and capabilities can cost upwards of $1000.

-

Barcode Software:

Barcode software is used to generate and manage the Code 128 barcodes. There are several types of barcode software available, including standalone software and integrated software that can be used with other business systems. The cost of standalone barcode software can range from $50 to $500, while more advanced integrated software can cost upwards of $2000.

-

Label Design Software:

Label design software is used to design and print the labels or tags that contain the Code 128 barcode. This software can range from basic design software to more advanced graphic design software. The cost of label design software can range from $50 to $500.

-

Barcode Labels or Tags:

The cost of barcode labels or tags can also impact the overall cost of implementing a Code 128 barcode system. The cost of barcode labels or tags can vary depending on the material, size, and quantity required. Barcode labels or tags can be purchased in bulk, which can help to reduce the cost per label.

-

Barcode Scanner:

-

Additional Costs:

There may be additional costs associated with implementing a Code 128 barcode system, such as training and support. It is important to consider these additional costs when budgeting for a barcode system.

-

Training:

Training may be required for employees who will be using the barcode system. This training can include instruction on how to generate and read the barcodes, as well as how to use the software and hardware required. The cost of training can vary depending on the type and length of the training required.

-

Support:

Ongoing support may be required to maintain and troubleshoot the barcode system. This can include technical support, software updates, and maintenance services. The cost of support can vary depending on the level of support required and the provider.

In conclusion, the cost of implementing a Code 128 barcode system can vary widely depending on the specific needs and requirements of the organization or business. It is important to consider all the factors that can impact the cost when budgeting for a barcode system, including hardware and software costs, label costs, and additional training and support costs. By carefully considering these factors and researching different vendors and providers, organizations can find a barcode system that meets their needs and budget.