Barcodes are essential for tracking packages in the shipping industry, and several barcode types are commonly used to help ensure that packages are delivered accurately and on time. Some of the most commonly used barcodes in shipping include:

-

Code 39

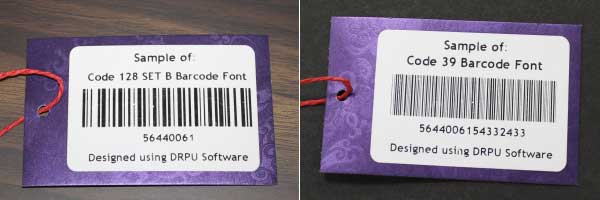

Code 39 barcodes are commonly used in the shipping industry to label packages and track them through the shipping process. This barcode is often used for smaller packages, such as envelopes or small parcels.

-

Code 128

Code 128 barcodes are used in the shipping industry to track larger packages, such as boxes or pallets. This barcode can encode more data than Code 39, making it useful for tracking larger items.

-

Interleaved 2 of 5

Interleaved 2 of 5 barcodes are used in the shipping industry to label and track packages, particularly in North America. This barcode is capable of encoding numeric data and is often used for packages that are being shipped domestically.

-

QR Code

QR codes are becoming increasingly popular in the shipping industry, particularly for use with mobile devices. This barcode can encode more data than traditional barcodes and is often used to provide customers with additional information about their shipment, such as delivery status and tracking information

The use of barcodes in the shipping industry has helped to improve package tracking and delivery, reducing the likelihood of lost or misdelivered packages. By using barcodes to label and track packages, shipping companies can deliver packages more efficiently and accurately, ensuring that packages arrive at their destination on time and in good condition.

Download and Install Shipping Barcode Software

Types of Barcodes Used for Shipping

There are several types of barcodes commonly used for shipping, but the most widely used ones are the Universal Product Code (UPC) and the Code 128.

-

UPC barcodes are used to identify products in retail stores, and they consist of a series of vertical lines and spaces of varying widths. Each UPC barcode includes a unique 12-digit number that identifies the product, and this number is scanned at the point of sale to retrieve pricing and inventory information.

-

Code 128 barcodes are used in logistics and supply chain management, including shipping and receiving. They can encode a wide range of characters, including letters, numbers, and symbols, and they are designed to be highly flexible and customizable. Code 128 barcodes can also include checksum digits to ensure accuracy and help prevent errors during scanning.

-

The main difference between barcodes used in shipping and those used in other industries is their purpose and the type of data they encode. Shipping barcodes typically include information about the shipment, such as the destination address, carrier information, and tracking number, while retail barcodes encode product-specific information such as the manufacturer and product code. Additionally, shipping barcodes may need to be more durable and resistant to damage and environmental conditions to ensure accurate scanning throughout the shipping process.

-

Other types of barcodes that may be used in shipping include the Interleaved 2 of 5 (ITF) barcode, which is commonly used in the distribution industry, and the Postal Numeric Encoding Technique (POSTNET) barcode, which is used by the United States Postal Service.

-

Compared to other barcode systems, shipping barcodes often include more information about package delivery and tracking, such as the recipient's address and the package's weight and dimensions. Additionally, shipping barcodes may be designed to be more durable and resistant to wear and tear, since they may need to withstand rough handling during the shipping process.

Future of Barcode Technology in Shipping Services

The Future of Barcode Technology in the packaging industry looks promising, with continued advancements that will improve automation, traceability, visibility, accuracy, and customer satisfaction. These innovations will help to improve package delivery and shipping services, making it easier and faster for packages to be delivered to their intended destinations.

The future of barcode technology in the packaging industry is likely to see continued growth and evolution, with innovations that improve package delivery and shipping services in several ways:

-

Improved Automation

Barcode technology can be used to automate many aspects of the packaging process, including product labeling and sorting, inventory management, and shipping logistics.

-

Enhanced Traceability

Barcode Technology continues to advance, we can expect to see even greater traceability of packages throughout the shipping process. This will help to improve delivery times, reduce errors, and provide customers with greater visibility into the status of their shipments.

-

Integration with Other Technologies

Barcode technology can be used in conjunction with other technologies such as RFID and GPS tracking to provide even greater visibility and control over the shipping process.

-

Improved Accuracy and Reliability

With the development of more advanced barcode scanners and readers, we can expect to see even greater accuracy and reliability in package tracking and delivery.

-

Customization and Personalization

Barcode technology can be used to create custom labels and packaging for individual products, providing customers with a more personalized and unique experience.

Posted By: Technogeek | Last Updated On: